11 Applications - Yokogawa WT5000 Precision Power Analyzer

- 11 Dec 2020

Click the application you're interested in below:

- Renewable energy development

- Efficiency of electric vehicles and powertrains

- Application in Lighting Drive Circuit Testing

- Medical equipment board power test

- Reactive power compensation device testing

- Robot servo motor test

- AC magnetic properties measurement of core materials

- Transformer Testing

- Wind Power Inverter Measurement

- Synchronous measurement system in rail transit

- Dishwasher Performance Testing

Renewable Energy Development

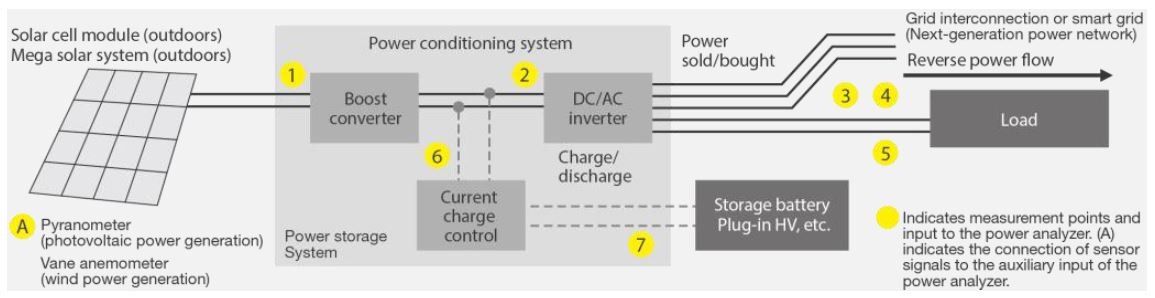

Overview - Energy generated by photovoltaic cell modules and wind turbines is converted from DC to AC by a power conditioning system (PCS). Minimizing losses in these conversions improves the efficiency in the overall energy system.

Key requirements

- High precision measurements from 6 AC phases for wind power generation, and 3 DC & 3 AC phases for PV generation.

- Harmonic evaluations of inverter signals due to superimpositions from switching circuits.

- Measure the amount of power sold/bought in grid interconnection and of battery charge/discharge.

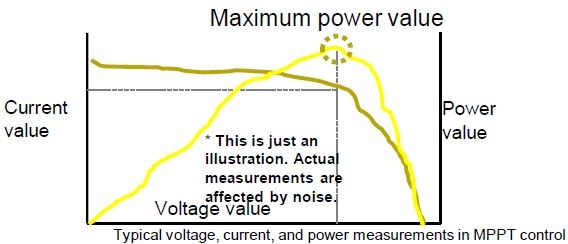

- Measuring instantaneous peak power in MPPT control of photovoltaic power generation.

The WT5000 advantages:

Multiple channels and wide input range

Evaluate PCS efficiency using 7 input channels for simultaneous measurements from the inputs and outputs of boost converter, inverter, and storage battery. WT5000 provides highest power accuracy:

- 0.01 % of reading + 0.02 % of range (50/60Hz)

- 0.02 % of reading + 0.05 % of range (DC)

Harmonic distortion factor measurement

A harmonic measurement function enables measurement of harmonic components to compute and display total harmonic distortion factor (THD)

Energy bought/sold and charged/discharged

The WT5000 enables the integration of current (q), apparent power (WS), reactive power (WQ), as well as the effective power integration in sold/bought power and charge/discharge modes.

Maximum power value measurement

The WT5000 is capable of measuring not only the voltage, current, and power but also the voltage, current, and power peak values for both plus (+) and minus (−) sides separately.

Efficiency of electric vehicles and powertrains

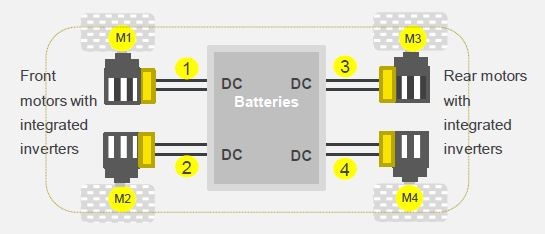

Case 1: 4 DC signals + 4 motors - Modern drive systems with integrated inverters do not allow access to the AC signals. Here one of the main measurement tasks is the overall drive train efficiency from DC to mechanical power. The example shows 4 DC measurements (1 to 4) with the corresponding 4 mechanical power measurements (M1 to M4).

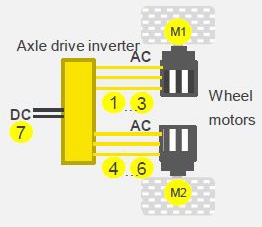

Case 2: 1 DC signal + two 3-phase AC signals + 2 motors - Drive system with inverter and 3 phase motor per wheel. Overall drive measurements can be easily performed by one WT5000.

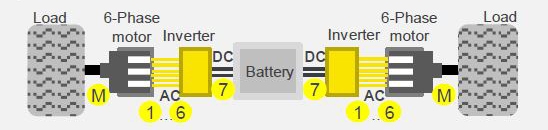

Case 3: (1 DC + 1 6-phase AC + 1 motor) x 2 - Drive system with inverter and 6 phase motor per wheel. Overall drive measurements can be easily performed by master-slave synchronization of 2 WT5000s.

Overview - From R&D to manufacturing and compliance testing, measurement of powertrain not only require progressively greater accuracies but also consistency in measurement over the specified ranges and conditions.

Key requirements:

- Measurements from multiple phases for battery, inverter and motor.

- Evaluation of multiple motor characteristics such as torque, rotation speed & direction, slip etc.

- Evaluation of multiple 6-phase motor systems

- Harmonic evaluations of inverter signals due to superimpositions from switching circuits.

The WT5000 advantages:

7 input elements

Up to 7 power channels make it easy to evaluate the electrical, mechanical, total power and efficiency of electrical vehicle powertrains.

Multiple motors evaluation

- One unit of WT5000 is capable of 2 sets of torque & A/B/Z phases or 4 sets of torque & rotation speed. (/MTR1 or /MTR2 option).

- Line filter can be set for pulse signal of motor torque and speed to reject noise.

Master-Slave synchronization

- Up to 4 units of WT5000 can be connected for synchronization measurement.

- Up to 28 power channels and 16 sets of motor torque and speed can be measured simultaneously.

Harmonics and dual harmonics

- Fundamental frequency of WT5000 is from 0.1Hz up to 300kHz and can meet motor testing at various rotation speeds.

- Max. order of harmonics: 500 order.

- Simultaneously measure harmonic parameters on two different fundamental frequencies.

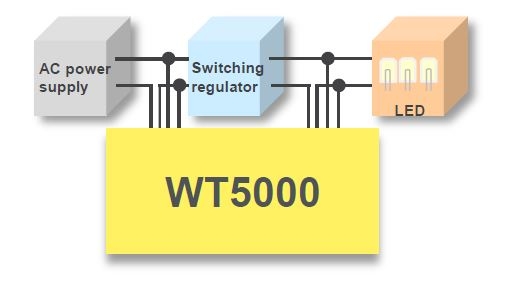

Application in Lighting Drive Circuit Testing

Overview - In recent years, fluorescent and incandescent lamps have been gradually replaced by longerlife, lower-energy LED lamps. In order to further improve the efficiency of LEDs, engineers are working to improve the power conversion efficiency of LED driver circuits (drive modules). Engineers need to measure the electrical parameters of the drive circuit.

Key requirements:

- Evaluating the LED driver circuit requires a multi-channel, high-precision, wide-bandwidth power analyzer.

- Wide input ranges of voltage and current, can test a variety of supply voltages, and can also test electrical parameters in normal and standby states

- Display values and waveforms or values and trends simultaneously

- Overall evaluation of current consumption, power consumption and efficiency

- Harmonic analysis

The WT5000 advantages:

Multiple channels and high accuracy

Up to 7 power channels make it easy to evaluate the current, power and efficiency of LED drive circuit.

Bandwidth:

- 5MHz for current

- 10MHz for voltage

Power accuracy:

- 0.01 % of rd + 0.02 % of fs (50/60Hz)

- 0.02 % of rd + 0.05 % of fs (DC)

Wide input ranges of voltage and current

Voltage range:

- 1.5/3/6/10/15/30/60/100/150/300/600/1000 (1500VDC)[V]

Current Range:

- 5m/10m/20m/50m/0.1/0.2/0.5/1/2/5 [A] for 5A module

- 0.5/1/2/5/10/20/30 [A] for 30A module

Flexible display form, displayed independently or in combination

Data such as values, waveforms, trends, harmonic lists, etc. can be displayed. It can also display the combination of “Value + Waveform”, “Value + Trend”, etc. while viewing the values, it is also possible to check the dynamics of each parameter.

Harmonics and dual harmonics

- Fundamental frequency of WT5000 is from 0.1Hz up to 300kHz.

- Max. order of harmonics: 500 order Simultaneously measure harmonic parameters on two different fundamental frequencies.

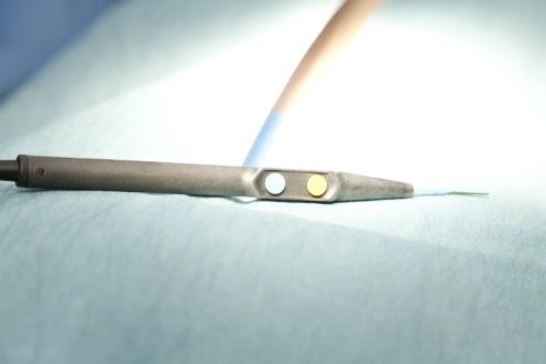

Medical equipment board power test

Overview - In general-purpose medical equipment, it is necessary to strictly control the power consumption and current conditions of each circuit board. So that engineers can provide an optimized design based on safety.

Key requirements

- Evaluate the power consumption of each board in high accuracy.

- High-frequency signals are used in medical equipment, and test instruments with wide bandwidth are required to get the correct value.

- Multi-channel, to evaluate the energy consumption relationship of each board under running conditions.

- Clear waveform display, reference to the state of the original waveform while viewing the numeric data

The WT5000 advantages:

High precision

- Provide high-precision power testing to meet test needs. 0.01 % of reading + 0.02 % of range (50/60Hz)

- 0.02 % of reading + 0.05 % of range (DC)

Wide test bandwidth

- Power bandwidth: DC, 0.1 Hz to 1M Hz;

- 5M Hz for current (design value);

- 10M Hz for voltage (design value)

Multi-channel input, Flexible selection

1,2,3,4,5,6 and 7Elements mixed installation is available. User can choose the amount of channels according to their needs.

Clear display of high sampling waveform

- In addition to the conventional numerical display, waveforms can also be displayed.

- High-precision sampling of approximately 10 MS/s and 18-bit AD allows for the detection of any rapidly changing anomalies.

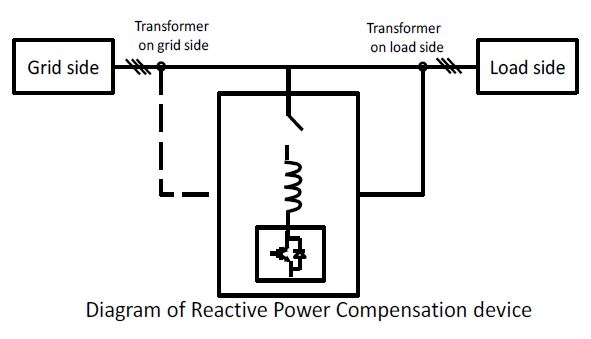

Reactive power compensation device testing

Overview - The reactive power compensation device plays a key role in dealing with the power quality problem caused by a large number of non-linear loads connected to the power grid. Among them, power factor, harmonic and other test items are particularly important.

Key requirements

- Do 3-phase testing on the grid side and the output side of the reactive power compensation device

- Harmonic analysis for voltage and current.

- Accurate testing of power factor during constant power factor adjustment

The WT5000 advantages:

Multi-channel

Up to 7 channels can simultaneously test the three-phase system of the grid side and output side of reactive power compensation device.

High precision

- 0.01 % of reading + 0.02 % of range (50/60Hz)

- 0.02 % of reading + 0.05 % of range (DC)

Harmonic function

- It can perform up to 500 order harmonic analysis on voltage, current and power.

- Support dual harmonic analysis.

High precision power factor measurement

Power factor accuracy up to: 0.02% of apparent power for accurate measurement of power factor.

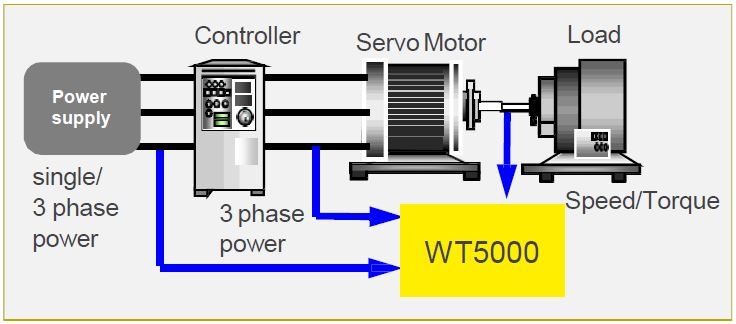

Robot servo motor test

Overview - Servo motors are widely used in automation equipment such as robots and CNC (Computer Numerical Control) machine tools. It is necessary to test the voltage, current, input power, mechanical power and efficiency of the servo motor and controller.

Key requirements

- Measuring servo motor mechanical power and efficiency

- Necessary to measure the controller input voltage, current, power and servo motor input voltage, current, and power.

- Harmonics analysis of voltage and current

- Robot overall power test

The WT5000 advantages:

Measurement of electrical parameters with high precision

WTX has the highest precision:

- 0.01 % reading + 0.02 % range (50/60Hz)

- 0.02 % reading + 0.05 % range (DC)

Multi-channel implementation of all aspects of testing

- Up to 7 channels measure the input power of the controller and the change in motor output power in the motor control.

- During the operation of repeating the acceleration and deceleration, the voltage RMS value, the current RMS value, and the power can be captured.

Harmonics analysis function

- Up to 500 order harmonic analysis.

- The dual harmonic measurement function can simultaneously perform harmonic test on the motor controller input and motor input to ensure the synchronization of measurement results.

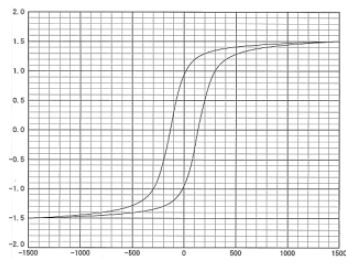

AC magnetic properties measurement of core materials

Overview - As the EV industry continues to evolve, development engineers are increasingly rigorous in measuring motor losses, as this will directly affect the endurance of the vehicle being developed. The iron loss test of the motor is one of the most important.

Key requirements

- High-precision measurement over a wide frequency range, especially at low power factor

- User can calculate magnetic field strength and magnetic induction measurement.

- The motor's electrical power consumption, mechanical power consumption, efficiency, copper loss, and iron loss are simultaneously displayed.

- User needs to accurately measure the charge and discharge of the battery

The WT5000 advantages:

High precision measurement

- 0.01 % of reading + 0.02 % of range (50/60Hz)

- 0.02 % of reading + 0.05 % of range (DC)

Influence of Power Factor: When λ= 0, ± 0.02% of reading of S for 45Hz to 66Hz

User-defined measurement

- The user can edit the measurement project formula as needed.

- Customize magnetic field strength measurement formula.

- Customize magnetic induction measurement calculation formula.

Flexible display form, displayed independently or in combination

Data such as values, waveforms, trends, harmonic lists, etc. can be displayed. It can also display the combination of “Value + Waveform”, “Value + Trend”.

EV battery, inverter, motor efficiency, iron loss measurement

One WT5000 can measure the related items of electric vehicles such as battery charge and discharge, inverter efficiency, motor efficiency, and motor iron loss.

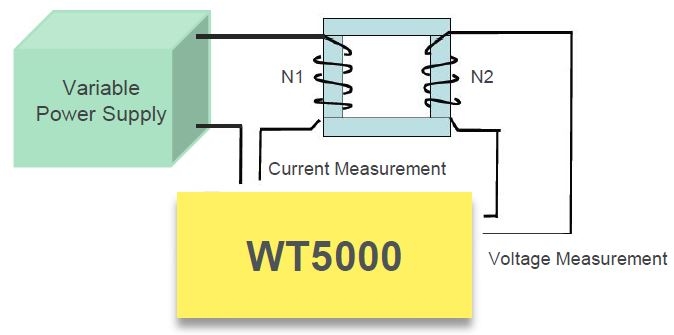

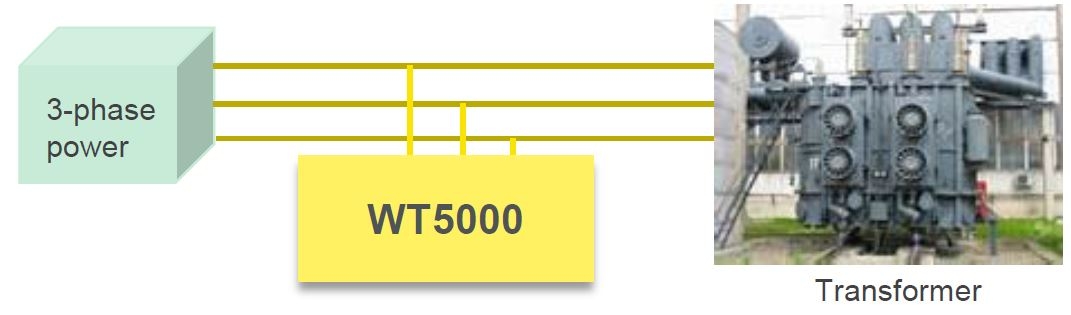

Transformer Testing

Overview - In the power generation and distribution industries, the power supply company and transformer manufacturers are particularly concerned about the economic effect of transformer losses. Therefore, the accuracy of the measurement system becomes especially important.

Key requirements

- Accurately measure 3-phase transformer’s voltages and currents

- In the transformer load test, the phase difference between voltage and current is close to 90°, and the power factor is close to zero.

- It is necessary to measure both the RMS value and the average value. The no-load loss is corrected according to the formula.

The WT5000 advantages:

High precision measurement

WT5000 has excellent angular accuracy and can accurately measure power values under extremely low power factor conditions, meeting the test requirements of transformers under no-load and load conditions, and accurately estimating transformer losses and other parameters.

Power accuracy:

- 0.01% reading + 0.02% range (50/60Hz)

- 0.02% reading + 0.05% range (DC)

Custom operation

It is convenient to carry out the calculation of the average value of the 3-phase RMS voltage, the average value and average line voltage.

Amendment to IEC60076 standard

The transformer no-load loss can be corrected according to the IEC60076 standard.

Harmonic measurement

The number of harmonics can be specified and the IEC formula is supported to calculate harmonics.

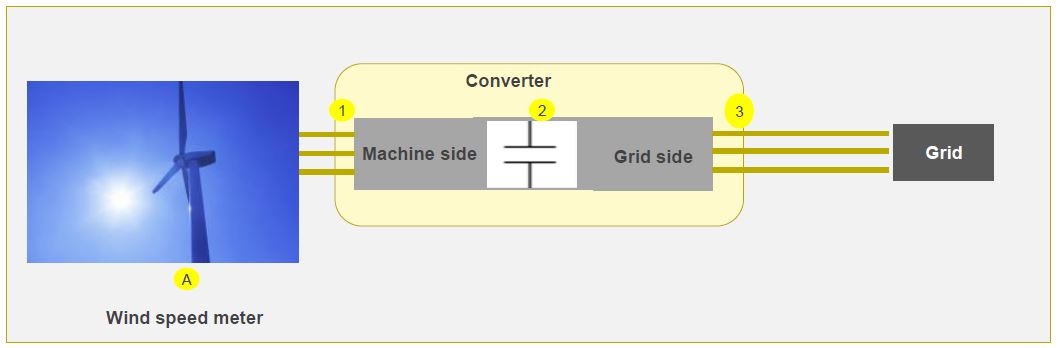

Wind Power Inverter Measurement

Overview - The energy generated by the wind turbine is converted from AC to DC by the converter and then converted to AC at the grid frequency. Reducing the losses in these conversions is critical to increasing the efficiency of the entire wind power system.

Key requirements

- High-precision 6 AC voltage and current channels measure the power of the machine side and the grid side respectively.

- One DC voltage and current channel measures the DC power during the conversion process.

- At the same time, the harmonic components of the machine side and the grid side are measured.

- Measure the efficiency of the entire system.

- Use aux sensors to record the power of the system at different wind speeds.

The WT5000 advantages:

Multi-channel wide input range

The 7 input channels are used to evaluate the wind turbine converter efficiency for simultaneous measurement on the machine side, grid side, and intermediate DC conversion.

WT5000 offers the highest power accuracy:

- 0.01% reading + 0.02% range (50/60Hz)

- 0.02% reading + 0.05% range (DC)

Dual harmonic measurement

The dual harmonic measurement function measures both the machine side and the grid side harmonics up to 500 order harmonics.

Long time data recording

When the wind power plant requires long-term data logging, WT5000 provides up to 32GB of storage capacity for data logging.

Auxiliary sensor detects other parameters

Using an aux sensor, parameters such as wind speed can be measured to evaluate the status of the wind turbine at different wind speeds.

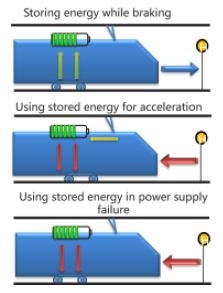

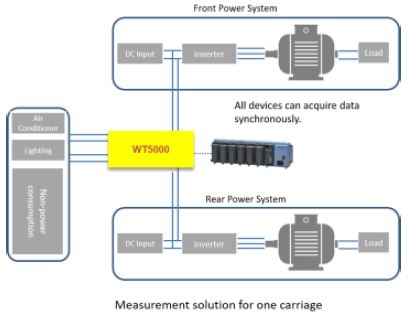

Synchronous measurement system in rail transit

New Urban Rail Transit system

Overview - The new urban light rail transportation project is equipped with a battery energy storage system and energy feedback technology, which can recover electric energy during the braking process, and continue to drive by enabling the energy storage battery in the case of extreme special power failure.

Key requirements

- At least 4 power meters measure voltage, current, power, efficiency, harmonics and other parameters simultaneously. Each unit requires more than 6 input elements.

- The power analyzer on one train needs to be synchronized to start/stop ±Wh, ±Ah measurement.

- The multi-point temperature signals need to be acquired synchronously in real time and recorded in synchronization with the power analyzer data.

The WT5000 advantages:

Energy storage system

Multi-channel input system

- Supports up to 7 voltage/current output units and two motor test functions.

- Support multiple simultaneous measurements and software remote control

The WT5000 can measure up to four simultaneous measurements and simultaneously control and collect data via WTviewerE software.

Support charging and discharging integration

The WT5000 supports current integration (q), apparent power integration (WS), and reactive power integration (WQ).

Support Modbus protocol

The Modbus protocol allows the WT5000 to be connected to Yokogawa's data acquisition system, which reads the WT data and saves it in sync with the acquired temperature data.

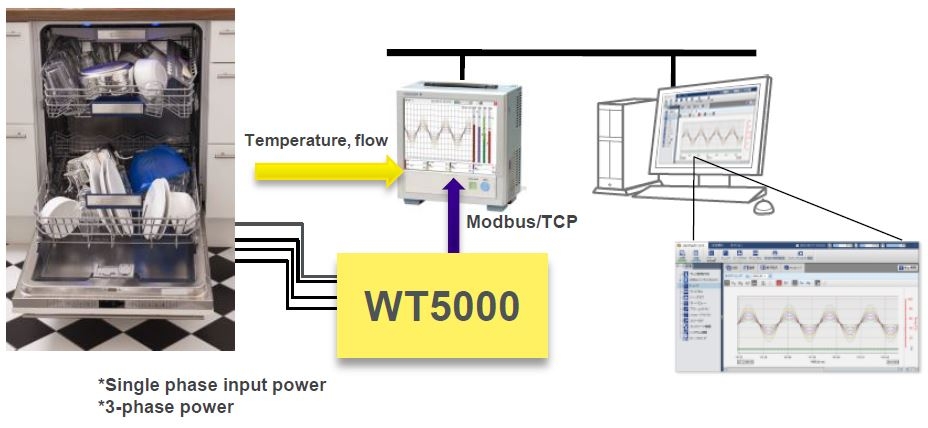

Dishwasher Performance Testing

Overview - In the performance test of the dishwasher. Customers need to record flow, temperature, power, etc. WT5000 seamlessly transfer power parameters to Yokogawa paperless recorder GP10/GP20 via Modbus/TCP. GP10/GP20 also records temperature and flow data.

Key requirements

- The power meter measurement data is required to be collected synchronously with the temperature and flow data.

- The input power is required to be measured simultaneously with the three-phase output power, and the efficiency is needed.

- Analyze the input current harmonics and make energy consumption measurements.

- Data can be recorded for a long time, and the computer and the host can record in synchronization to ensure data security.

The WT5000 advantages:

Multi-channel input system

Supports up to 7 voltage/current input units and two motor test functions.

High precision and wide bandwidth

- 0.01 % of reading + 0.02 % of range (50/60Hz)

- 0.02 % of reading + 0.05 % of range (DC)

- Current bandwidth: 5MHz, voltage bandwidth: 10MHz

Dual system harmonic distortion test

Supports dual harmonic measurements with up to 500 harmonic analysis.

Support multiple integration modes

The WT5000 supports current integration (q), apparent power integration (WS), and reactive power integration (WQ).

Support Modbus/TCP protocol

The Modbus/TCP protocol allows the instrument to be connected to Yokogawa's data recorder system, which reads the WT’s data and saves it in sync with the acquired temperature data.

Yokogawa WT5000 Precision Power Analyzer

The New Yokogawa WT5000 is the first of a new generation of Precision Power Analyzer that offers exceptional measurement accuracy of ± 0.03% combined with stability, noise immunity and plug-in modular flexibility to meet the measurement needs of today’s developers of energy-efficient systems.

In rapidly evolving industry sectors like electric vehicles, renewable energy and energy efficient technologies, the need for reliability in testing to enhance safety, efficiency and performance has never been greater. Changing application needs and evolving international standards call for custom measurements and consistent accuracy, and in the WT5000 Precision Power Analyzer, engineers have a versatile platform that not only delivers reliable measurements today, but is ready for the challenges of tomorrow.