7 Things To Consider When Selecting A Deadweight Tester

- 11 Dec 2020

The deadweight tester (DWT) is a very robust and flexible pressure measurement standard. This blog post is intended to simplify the process of selecting the right deadweight tester for your application. The following considerations will help you get started:

- Pressure range

- Pressure media

- Pressure generation options

- Weight increments

- Accuracy

- Adapters

- Available models

7 Things to consider when selecting a deadweight tester:

1. Range

The first thing to consider is the pressure range. One of the advantages of a DWT is the wide range of instruments that it can cover. The DWT is an inherent percent-of-reading device, meaning that its performance actually improves as it is used at pressures below full scale. There is a lower breakpoint, normally 10 % of full scale, where the specification ceases to be percent of reading.

When selecting the range of a deadweight tester, first consider the highest pressure that needs to be generated. The full scale needs to be greater than this. Since the accuracy is a percent of reading specification, it is okay to consider possible future expansion and select a DWT that has a higher full scale than what is currently needed.

The next step is to confirm that the unit can generate the lowest pressure that is required. As stated, the performance is less than ideal when the pressure being generated is below 10 % of the full scale. Applications that require both low and high hydraulic pressures can be handled using dual piston units. These units are provided with both a low range and high range piston/ cylinder. Switching between the low range and high range on a Fluke Calibration DWT is as simple as removing the masses from one piston and placing them on the other. No valves need to be switched.

Many pneumatic devices also support measuring gauge mode pressures that are below atmospheric pressure. This is often referred to as negative gauge or vacuum mode. To support the calibration of these devices, a DWT can be provided with a vacuum piston, where the piston is suspended with the weights below it. A partial vacuum is then generated above the piston to float the piston. The Fluke Calibration P3000 is available in configurations of vacuum only, positive pressure only, or combined vacuum and pressure. Due to the relatively low additional cost of having a combined pressure/vacuum system, they are normally preferable.

2. Media

The next thing to consider when selecting a DWT is the medium to be used. Often the choice of the medium is dependent upon the pressure range required. Pneumatic, or gas, instruments are ideal for lower pressure ranges. Gas is preferred whenever cleanliness is required. In addition, using gas reduces the impact of head height corrections. However, at higher pressures it is necessary to use water or oil.

The usefulness of gas as a medium is limited to approximately 2000 psi. There are two reasons for this. First, there is more risk of explosion at high gas pressures, and that is a safety concern. Second, generating high gas pressure will require expensive intensifiers or gas boosters. Using oil or water eliminates these issues. Since water is not a very good lubricant, oil is preferable when allowed.

One advantage of liquids is they are incompressible. This allows a small change in the volume of the system (through a screw pump) to result in large changes in pressure. The most common approach is to use a mineral oil as the medium. This is ideal in that it assists in lubricating the piston and cylinder. The downside to using oil as a medium is it now introduces the device under test to possible contamination.

If a device under test cannot be exposed to oil, then there are a couple of options available. First, in certain devices you can use water instead. Another option is to use a liquid-to-liquid separator. The separator allows you to use one liquid in the device under test and another in the DWT. Second, certain ranges are available with water as the media. This allows for the device under test to be connected straight to the deadweight tester without oil contamination.

3. Pressure generation

A DWT is a complete solution that encompasses both the ability to measure the pressure as well as generate the pressure.

To increase pressure in a hydraulic deadweight tester, a priming pump is used. Fluke Calibration P3100 and P3200 Series Deadweight Testers have a priming pump included standard in the device. The priming pump can also be used to remove gas from the system.

For low gas pressures, the pressure is generated using a hand pump. Higher gas pressures (more than 2 MPa or 300 psi) require the use of an external source, such as a nitrogen bottle. Even when pumps are rated to higher pressures, users will normally find them difficult to use because of the forces involved.

Generation of negative gauge, or vacuum, is similar in concept to positive pressure. For lower vacuum pressures with small volumes a built in hand pump will be sufficient. For larger volumes or higher vacuums, an external vacuum pump may be desirable.

4. Weight sets

Deadweight testers use a precision piston-gauge system consisting of a vertically mounted, piston and cylinder assembly, and accurately calibrated weight masses that are loaded onto the piston. Weight sets are available in a variety of units of measure such as psi, inH₂O or MPa, and are calibrated to match a specific deadweight tester. If more than one unit of measure is desired then, additional weight sets called conversion weight sets, can be purchased in the desired units and calibrated to match the same deadweight tester.

On certain deadweight testers, a fine increment weight set is also available. This is useful when calibrating a wide range of devices by allowing for more discrete pressure set points. These smaller weights supplement the larger weights to produce fine incremental pressures. For more information on the standard weight sets provided as well as the fine increment weight sets, please see document 4090591, “Pressurements Deadweight Tester’s Weight Increments.”

5. Accuracy

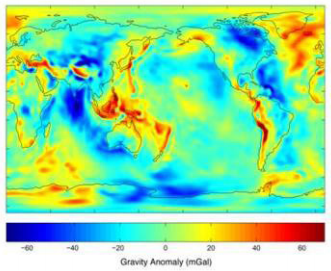

Like most measurement systems there are many factors that affect your accuracy. Potentially, the largest factor affecting accuracy in a deadweight tester is local gravity. Gravity varies slightly from one location to another (see map). This has an impact on the nominal pressure increments of a deadweight tester. To overcome this issue, at the time of manufacture Fluke Calibration trims the weights to produce the correct nominal pressures at your location. This is an advantage of buying a new deadweight tester and having the manufacturer trim the weights for you.

Deadweight testers are available in the marketplace at varying accuracy classes. When comparing accuracy specifications it is important to realize that those values can only be realized under the right conditions. Better accuracies may require the users to make additional corrections not mentioned on the data sheet. For example, an accuracy of 0.006 % may only be valid if you correct for temperature and use a more accurate value for local gravity in your calculations.

Each Fluke Calibration DWT is available with standard accuracy or an improved accuracy option. Instruments with the improved accuracy option come standard with software to assist in the calculation of the generated pressure.

For better accuracies, a piston gauge may be appropriate. A piston gauge works on the same principle as a DWT but is designed, built, and operated in such a way to provide improved uncertainties.

6. Adapters

A DWT will include a test port to allow for the connection of the unit under test. Since one of the inherent features of a DWT is its flexibility, it is important that the test port connection be adaptable to multiple types of pressure devices.

The test port on a Fluke Calibration DWT is available with adaptors for various sizes and types, 1/8, 1/4, 3/8, and 1/2 NPT and BSP as well as M20 x 1.5 and M14 x 15 included standard. Due to the unique design of the Fluke Calibration test port, all of the above adapters are capable of providing leak tight seals to 140 MPa (20,000 psi) without the use of wrenches or PTFE tape.

7. Calibration

The measurements that you make with your deadweight tester are very important, and often influence decisions that have a big financial impact on your company. It is important to ensure that you have the highest quality calibration data backing up the measurements that you make. Fluke Calibration automatically provides an ISO 17025 accredited calibration for each DWT. With an ISO 17025 accredited calibration, you know that the calibration laboratory has been assessed by third party calibration experts to ensure that the technician training, environment, procedures, measurement uncertainty, equipment used and measurement traceability associated with the calibration all are performed to stringent requirements. Having your DWT accompanied with an ISO 17025 accredited calibration also reduces total cost to your company by reducing, or in some cases eliminating, the need for supplier audits, with a potential savings of hundreds or even thousands of dollars.

Some customers may require you to demonstrate that the calibration of your DWT is traceable to the International System of Units (SI), usually through a national metrology institute like NIST. When your DWT comes with an accredited calibration, this has been internationally recognized to provide sufficient demonstration of traceabilty. You won’t have to spend the additional time calling your calibration supplier and requesting additional documentation in order to prove that your measurements are traceable.

When your work is important, and your measurements matter, an accredited calibration is a great way to provide additional confidence in your measurement results and to demonstrate to your customers that you meet their quality requirements.

Models:

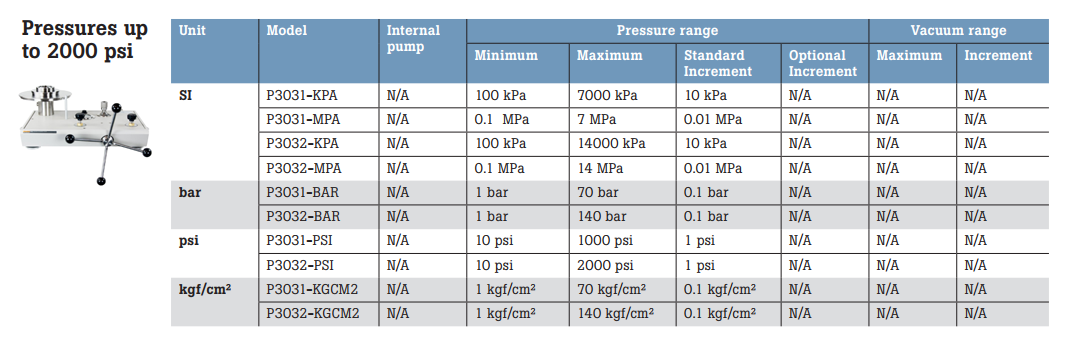

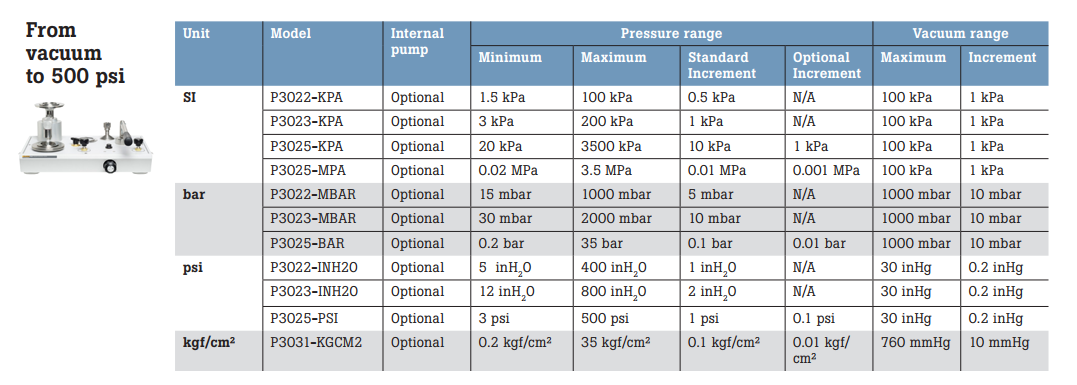

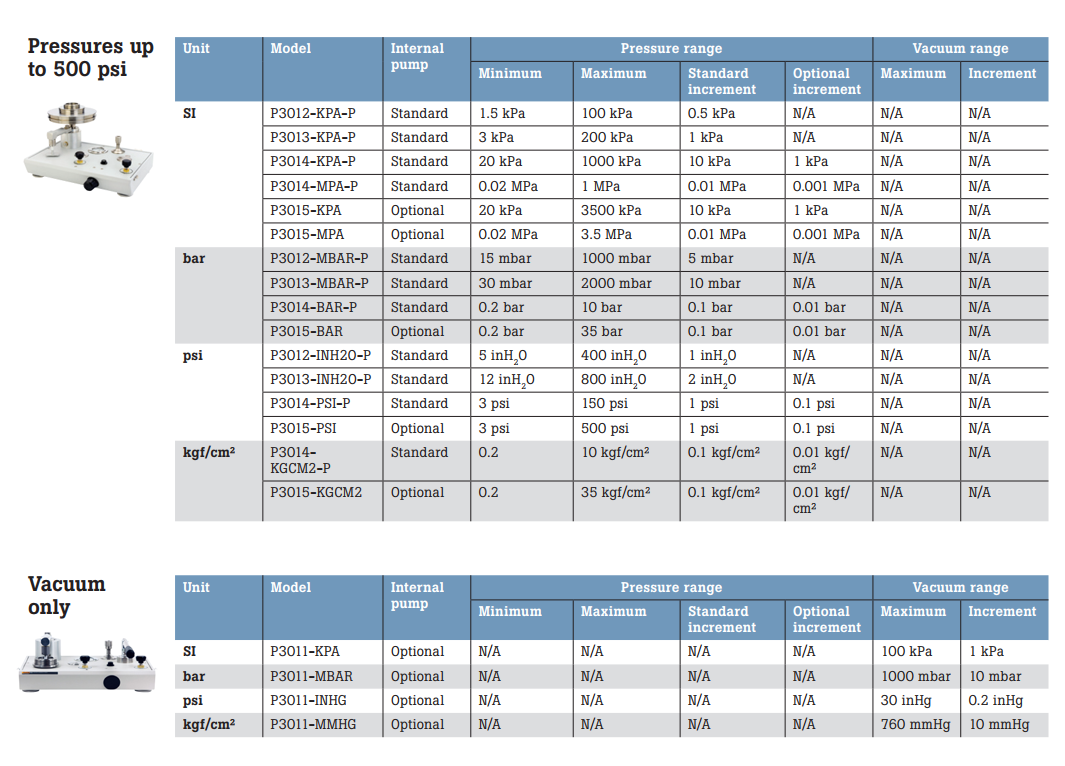

P3000 gas operated (pneumatic) deadweight testers

Proven, reliable, and clean pressure calibration from vacuum to 2,000 psi.

- 0.015 % accuracy standard, 0.008 % optional

- Piston-cylinder design provides stability and repeatability

- High quality needle valves provide optimum control

- Test station design provides quick connection without the need for PTFE tape or wrenches

Each unit includes:

- Weight Set trimmed to supplied local gravity

- Detachable lid

- High quality case

- Accredited calibration certificate

- Operating fluid (where applicable)

- Spare seals

- Adaptors for 1/8, 1/4, 3/8, 1/2 NPT and BSP and metric adaptors (M20 and M14)

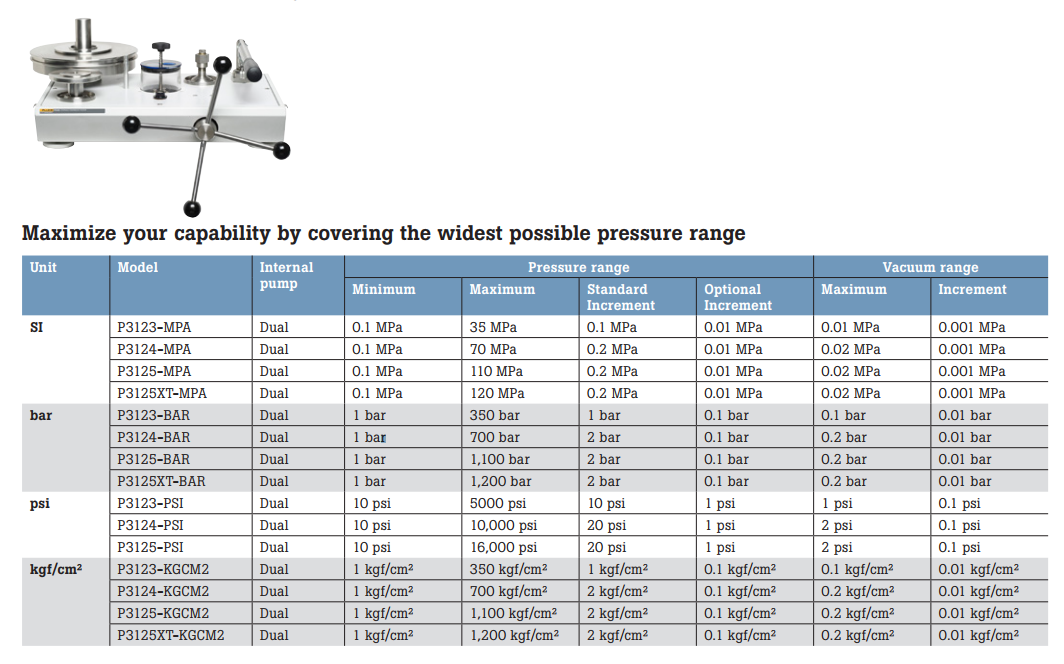

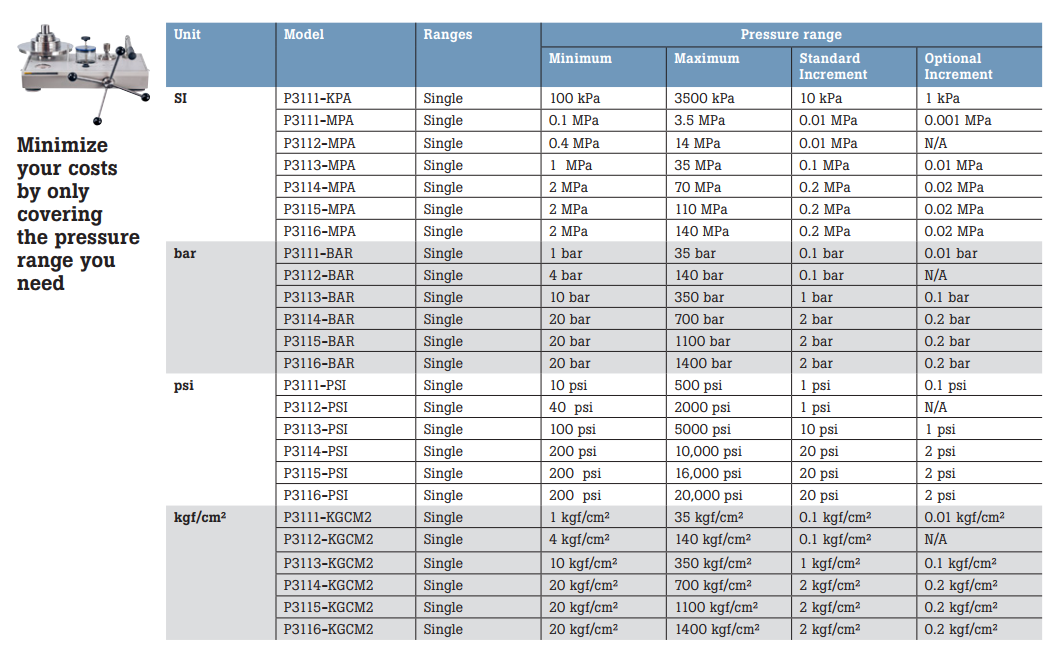

P3100 oil operated hydraulic deadweight testers

Operate safely and accurately at high pressures.

- 0.015 % accuracy standard, 0.008 % optional

- Built-in Priming Pump allows for quick purging and initial generation of pressure

- High quality screw press for pressure generation and fine control

- Clear reservoir allows for easy visual inspection of fluid cleanliness

Each unit includes:

- Weight Set trimmed to the supplied local gravity

- Detachable lid

- Accredited Calibration Certificate

- Adaptors for 1/8, 1/4, 3/8, 1/2 NPT and BSP and metric adaptors (M20 and M14)

- Operating fluid

- Spare seals

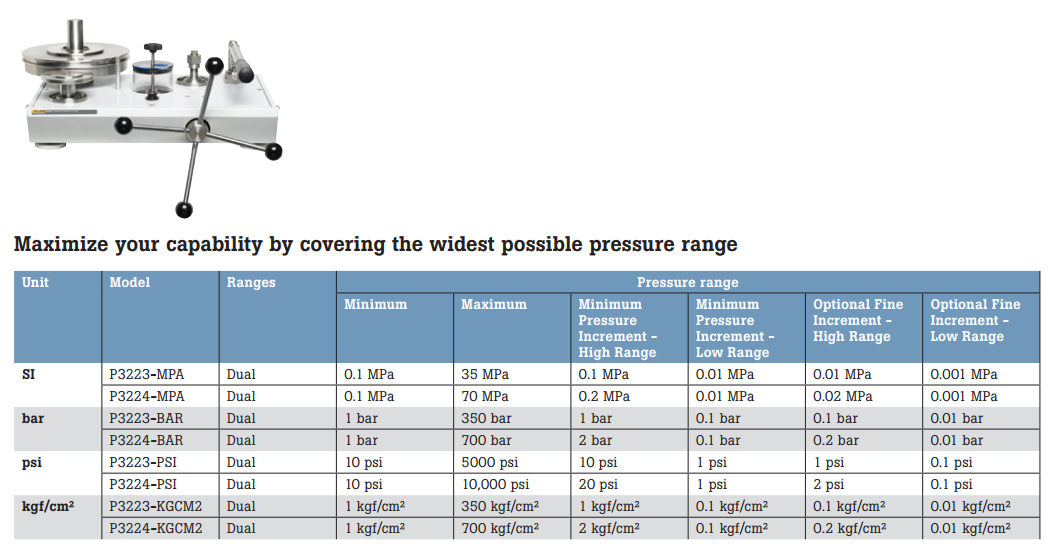

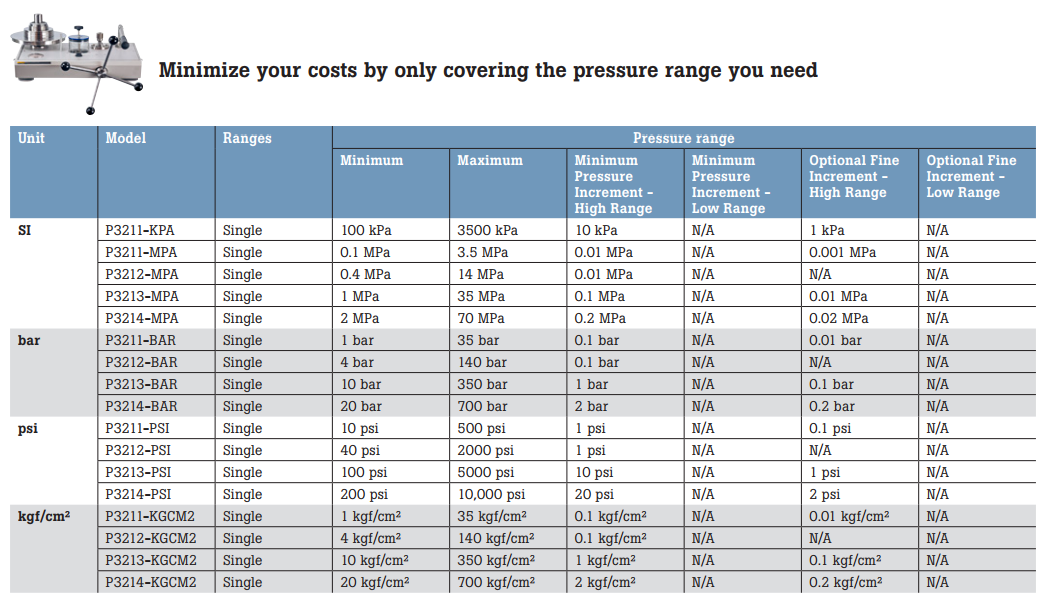

P3200 water operated hydraulic deadweight testers

An alternative to oil operated deadweight testers for media sensitive applications up to 10,000 psi.

- Uses distilled water as the operating fluid making it ideal for those applications where oil is not allowable

- 0.015 % accuracy standard, 0.008 % optional

- Built-in Priming Pump allows for quick purging and initial generation of pressure

- High quality screw press for pressure generation and fine control

- Clear reservoir allows for easy visual inspection of fluid cleanliness

Each unit includes:

- Weight Set trimmed to the supplied local gravity

- Detachable lid

- Accredited Calibration Certificate

- Adaptors for 1/8, ¼, 3/8, ½ NPT and BSP and metric adaptors (M20 and M14)

- Operating fluid

- Spare seals

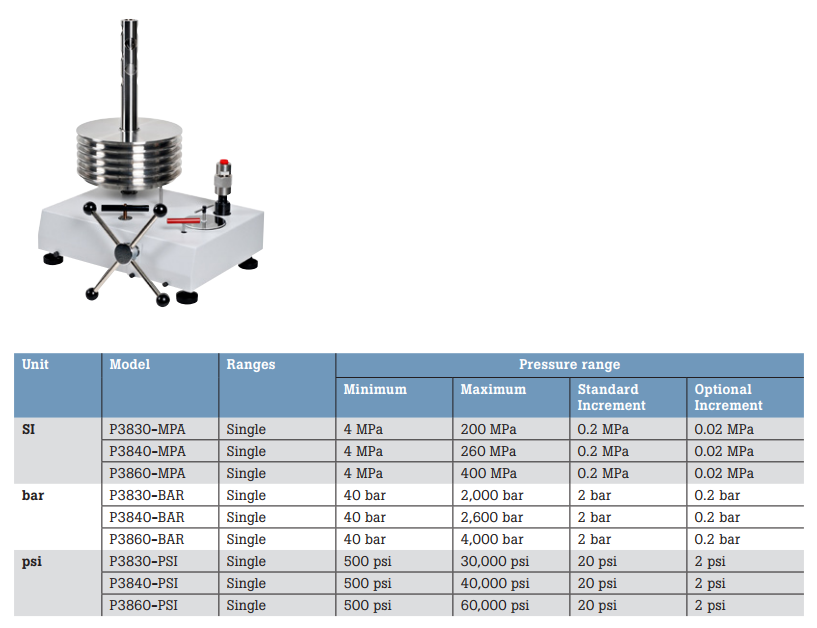

P3800 high-pressure oil operated hydraulic deadweight testers

- Standard accuracy of 0.02% Reading, 0.015% Reading available

- Includes built-in hand pump and intensifier for generating high pressures

- Tungsten carbide piston and cylinder provides long-term stability and durability

Each unit includes:

- Weight Set trimmed to the supplied local gravity

- Accredited Calibration Certificate

- Operating Fluid

- High Pressure Adaptors

Get 15% off on all Fluke Calibration 3xxx Series Deadweight Testers >

Content courtsey of Fluke Calibration