Electric Vehicle - Charging Systems

- 11 Dec 2020

Overview

Range anxiety - the worry that the battery will run out before a destination or charging point is reached - is among the major barriers for mainstream adoption of electric vehicles. As charging infastructures still need to be improved, battery efficiency in charging and regenerative braking systems are important.

Key Requirements

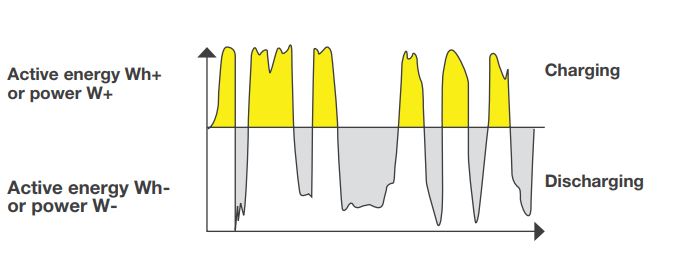

- Battery charging/discharging characteristics

- Measure positive and negative cycles of power

- Holistic view of charging and consumption efficiency

- Harmonic analysis at various rotation speeds

Fig 2. Battery charging and discharging characteristics

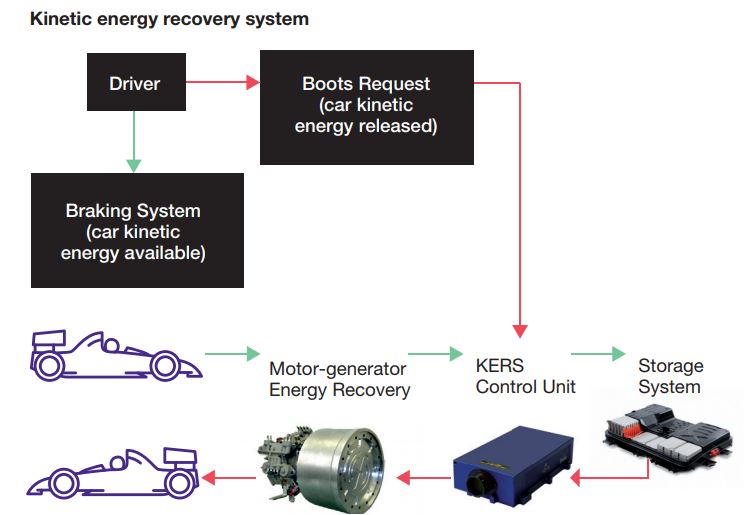

Fig 3. Schematic of the KERS system as used in Formula One racing cars

The WT5000 advantage

WT5000 helps automotive engineers improve conversion efficiency, shorten charging times and improve driving range by offering highly accurate analysis of charging discharging and overall electromechanical efficiency.

Battery charging & discharging characteristics

In integrated measurement, the battery charge and discharge can be evaluated. Instantaneous positive and negative values captured at 2MS/s high-speed sampling rate are integrated.

Overall mechatronic efficiency

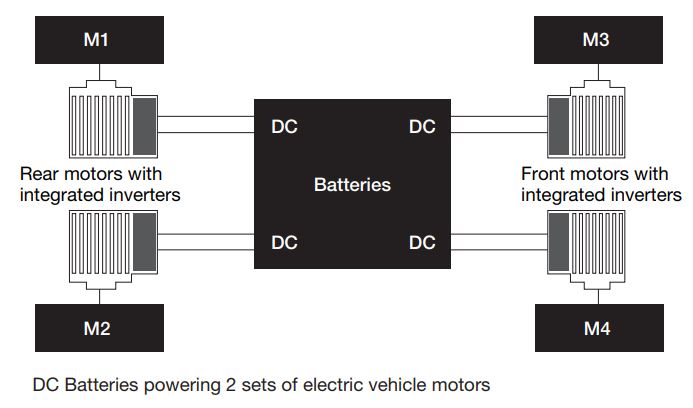

With power measurements on up to 7 input channels and a dual motor evaluation function the WT5000 is ideal for evaluating how well electric power generated by the charging system serves the mechatronic needs of the vehicle. It enables simultaneous measurements of voltage, current, power, torque, rotation speed, electrical angle and mechanical power.

Harmonics analysis & comparisons

Motor testing is performed at various rotation speeds. The WT5000 supports the lower limit frequency of 0.5Hz to make it possible to measure harmonics at a very low motor rotation speed without using an external sampling clock.