The Smarter Way to Characterize Components - GW Instek LCR-8200 Series

- 11 Dec 2020

The Smarter Way to Characterize Components - GW Instek LCR-8200 Series

GW Instek have launched a new series of high-frequency LCR meters - LCR-8200, which has four models and a maximum test frequency up to 30MHz. The series has a 7-inch colour display and features a high measurement accuracy (0.08%).

The measurement results can be presented numerically or graphically according to the selected measurement mode, allowing users to optimally interpret the characteristics of the DUT. At the same time, a full range of standard interfaces such as USB device / RS-232C / Handler and GPIB allows users to control the instrument by the most familiar interface without worrying about additional hardware investment costs.

The series also provides USB storage function when operating in the graphics mode. The measured characteristic curves and values of the DUT are saved for subsequent analysis. The wide variety of features of the LCR-8200 can help users easily respond to the test requirements of passive components in R&D, engineering, and production.

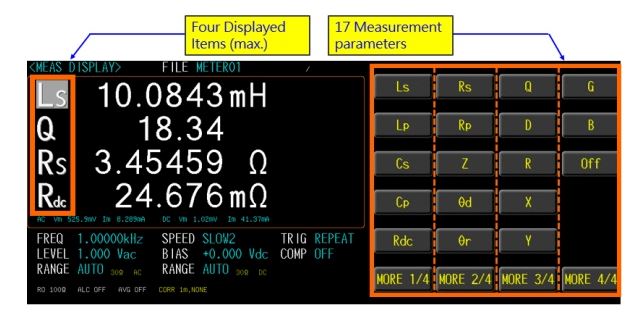

Under the numerical measurement mode, it is divided into MEAS measurement and LIST measurement. Under the MEAS measurement mode, users can select up to 4 (at least 1) desired measurement items from the 17 measurement parameters. Each selected measurement item can be set to compare (PASS/FAIL judgement) or to the BIN function to conduct judgement and sorting, so that users can easily learn the results of the measurement by color and sound.

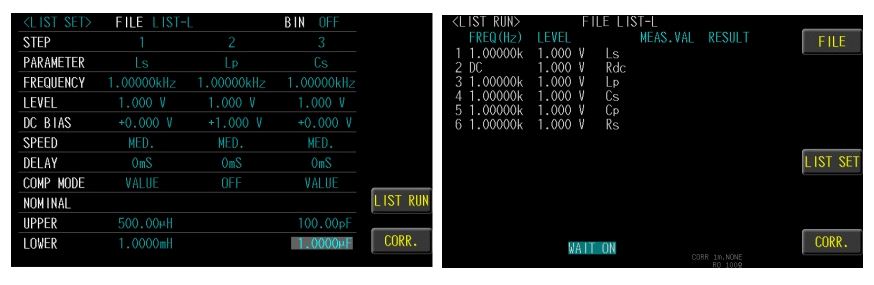

Under the LIST mode, users are allowed to set 15 test points and each test point can set parameters independently, including frequency/voltage/bias, and it can even set independent comparison function and numerical display mode (value, difference value, difference percentage). On top of that, under the LIST mode, the automatic trigger mode is also provided. After each LIST measurement is completed, the instrument will be in the mechanism of a standby trigger. Users only need to place the next DUT, and the LIST test can be automatically performed that saves time of repeatedly pressing the trigger button.

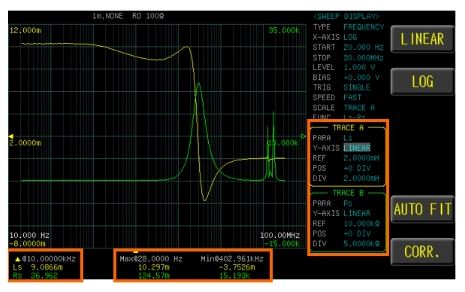

Under the graphical measurement mode, the DWEEP measurement provides the ability to sweep two parameters simultaneously (TRACE A/ TRACE B). The relative parameters of the sweep, including the sweep source (frequency, voltage or current), horizontal/vertical axis scale (LINEAR / LOG). speed, even adding a bias, can be set and tested according to the actual needs of users.

After the sweep is completed, the scale can be automatically adjusted according to the selected TRACE, so that the whole observation is clearer and easier to read. Other than that, the swept graphics (bmp) and values (csv) can be saved to the flash drive for subsequent analysis and applications.

Whether it is for measurement data collection during the test process or the collocation for the system integration, the LCR-8200 series offers the most comprehensive communications interfaces, including USB device, RS-232C, LAN for PC connection and even GPIB, which are all standard communications interfaces. Users can choose according to the habits of use and the convenience of the system architecture without any additional cost. In addition, the LCR-8200 series also provides a Handler interface for system integration of PLCs or sorters.

The Smarter Way to Characterize Components

The presentation of flexible measurement combinations

LCR-8200 allows users to select and arrange measurement parameters. Users can select at least one parameter to a maximum of four parameters from the 17 measurement parameters according to the measurement requirements and the presentation order can also be arranged in a desired manner. The set parameters can be stored in internal/external memory groups for subsequent recalls.

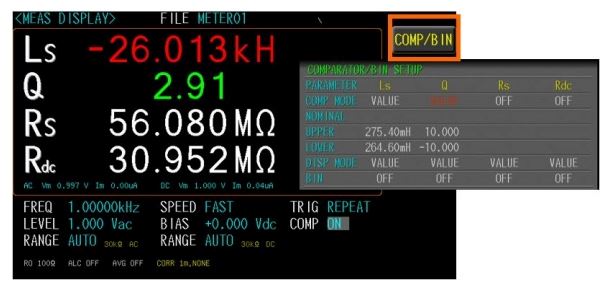

Independent setting judgement

Each selected test parameter can independently set judgement and comparison such as value, difference value or difference percentage. Additionally, the display method can also be based on value, difference value or difference percentage to self-define the presentation of test results, and the observation is more in line with the actual needs. In addition to using the warning sound, all the parameters set for comparison judgement will be displayed in different colours. "Red" means that the limit value is exceeded, and "Green" means that it is within the limit value, so that the judgement can be conducted smoothly under noisy environment.

LIST measurement

The 15-point LIST measurement mode provides measurement values at a specific frequency or voltage of the DUT, and each set point can set independent comparison and judgement. When the trigger mode is set to "AUTO", the display "WAIT ON" will appear on the measurement screen and LCR-8200 will detect the contact status of the fixture. When the DUT is connected, the test will start automatically.

Hyperbolic Sweep

Up to 2 characteristic parameters of the DUT can be swept at the same time. Sweep type (frequency/Vac/lac), axis for (LOG/LINEAR), sweep speed, even adding bias (internal), etc can be set according to the actual demands. After the sweep is completed, automatic adjustment can be used to obtain the best observation display. The movable cursor can be used to obtain the measurement result of the specific position. Swept displays and point values can be saved the flash drive via the USB host on the panel for subsequent analysis.

BIN Function

BIN settings for one specific parameter of the selected measurement parameters provide up to 9 BIN positions. Set the judgement basis for individual classifications according to the desired BIN methods (EQUAL/SEQUENTIAL/TOLERANCE?RANDOM) and limit value mode. (VALUE/delta/delta%). The result of this sorting can be obtained through the Handler interface. If directly connected to an external device such as a sorter, an immediate sorting can be performed.

Complete Standard Interfaces

Provides a variety of standard PC connection interfaces such as RS-232C, USB device, LAN, and GPIB industrial control interface to remotely control settings or read measurement results and other related information so as to substantially increase wok efficiency without having to pay for additional interface procurement costs. In addition, LCR-8200 also provides Handler interface for PLC external control or for the collocation of measurement integration of sorters.