Cooled vs Uncooled Thermal Imaging Cameras

-

By

S J Electronics

By

S J Electronics

- 18 Aug 2023

- 0 Comments

Cooled vs Uncooled: The Right Camera For The Job

In this article, we will be exploring the differences between a cooled and uncooled thermal camera, highlighting each camera's benefits, drawbacks and unique workplace applications to help you choose the right camera for your needs.

What is a Cooled Camera?

Cooled Cameras are thermal imaging sensors that include an integrated cryocooler, a device that decreases the sensor temperature to cryogenic levels (-150°C to -273°C). By drastically lowering the temperature, thermally-induced noise below the signal from the visible scene is minimised and provides the user with a much clearer and higher-resolution image.

Benefits of Cooled Cameras

- Precision: Cooled thermal imaging cameras stand out for their remarkable sensitivity and precision in detecting even the most subtle temperature variations

- SWIR/LWIR: Crafted to operate within the Shortwave (SWIR) and Midwave Infrared (MWIR) spectrum, they leverage the principles of blackbody physics to enhance thermal contrast. This translates to an ability to discern targets from backgrounds of similar temperatures, a crucial aspect of thermal imaging

- LWIR: Cooled cameras can also be designed to operate in the Longwave Infrared (LWIR) band, extending their usability. When pitted against uncooled thermal imaging cameras, the comparison clearly favors the cooled cameras, showcasing their unmatched sensitivity and prowess in temperature differentiation

High-Speed Capture

Cooled thermal cameras are ideal for capturing images and taking measurements of objects moving at high speed without motion blur distortion. This is achieved thanks to an incredibly fast response time and global shutter, which read out all pixels simultaneously, rather than line-by-line.

The ability to capture detailed and accurate measurements and images at high speeds makes cooled cameras the ideal tool for studying heat and movement in aerospace engines to stress-testing automotive tires and components.

Higher Resolution

The enhanced sensitivity of cooled cameras lets them use lenses with more or thicker optical elements, improving magnification without affecting the signal-to-noise ratio.

The enhanced magnification that cooled thermal cameras offer also presents a more cost-effective solution for longer-range imaging compared to uncooled cameras. Uncooled cameras are cheaper than their cooled counterparts by a wide margin but the high costs associated with longer-range lenses can make cooled cameras the cheaper option.

Sensitivity

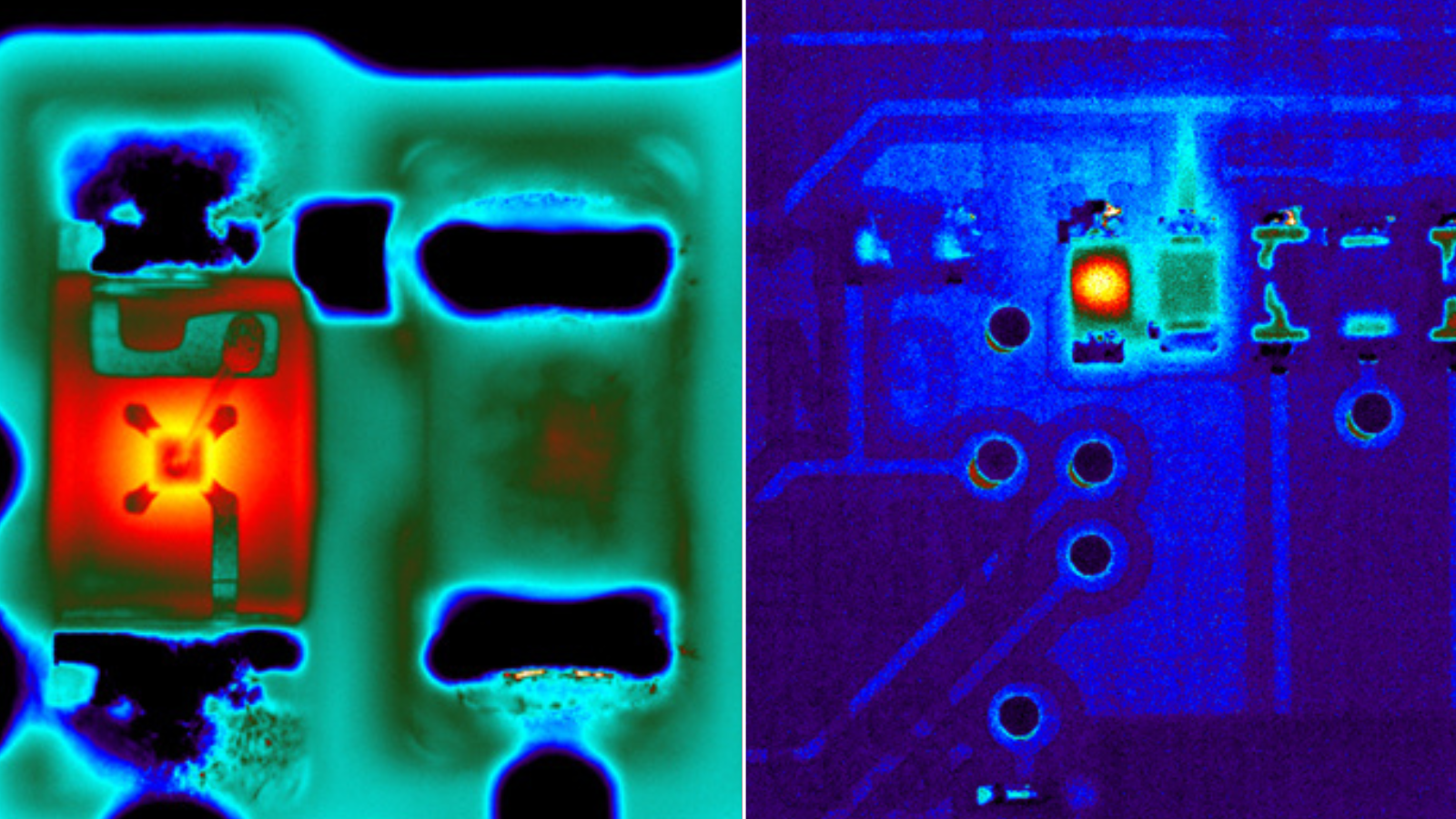

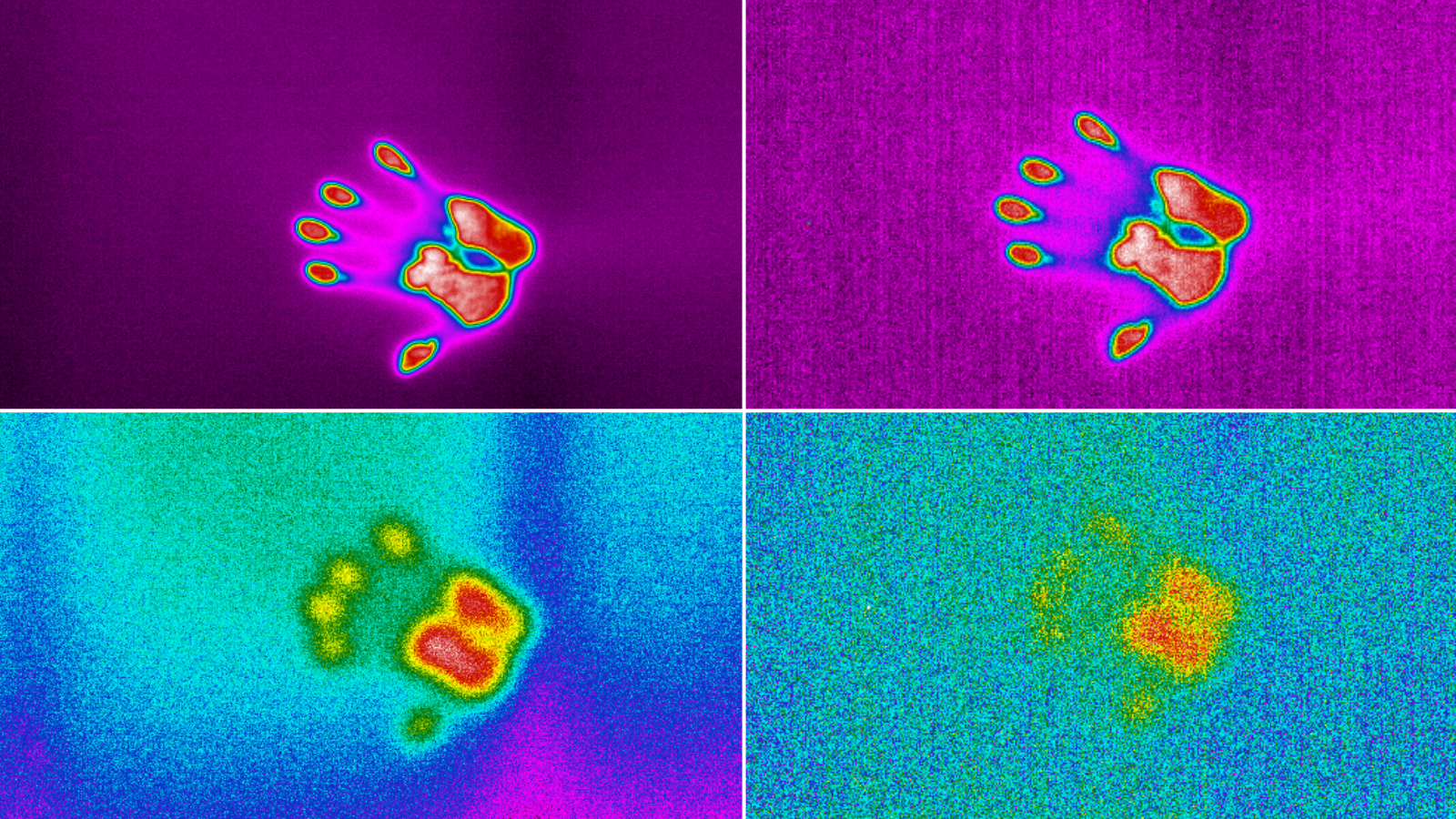

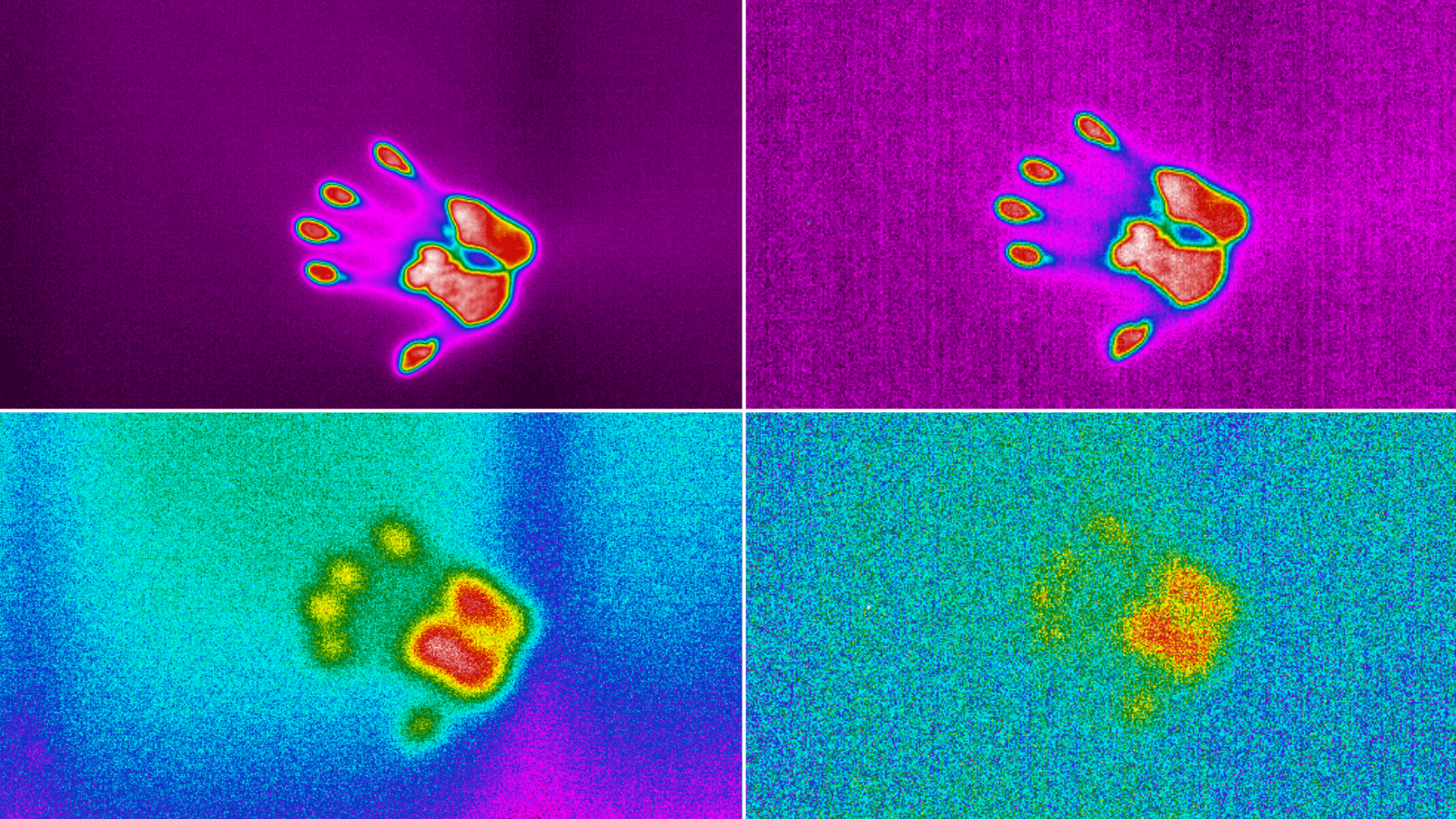

To demonstrate the value of improved sensitivity in cooled thermal cameras, the images above show a thermal handprint. The left images shown above depict the handprint immediately after the hand was removed, and the two images on the right after two minutes.

The cooled camera maintains most of the handprint's thermal signature, unlike the uncooled camera which only shows partial remains. Cooled cameras detect smaller temperature differences and for longer durations, revealing finer details and even faint thermal anomalies.

Disadvantages of Cooled Cameras

- Cost: Cooled thermal imaging cameras tend to incur higher manufacturing and upkeep costs due to the intricacies of their cooling mechanisms. These systems commonly employ cryogenic cooling components like Stirling or Joule-Thomson coolers which can increase the overall cost of the camera, in addition to the higher-spec lenses and components.

- Power Consumption: Cooled thermal imaging cameras use more power to sustain their cryogenic cooling mechanisms. This results in higher power usage when compared with uncooled cameras. Consequently, this poses challenges for battery longevity, especially in remote or resource-limited settings.

- Maintenance & Reliability: The cooling mechanisms in cooled cameras are complex and fragile, potentially resulting in increased upkeep needs and greater susceptibility to operational issues. Conversely, uncooled cameras typically boast sturdier construction with fewer components.

Recommended Cooled Cameras

A8583 Compact MWIR HD Thermal Camera

Unbeatable Resolution & Measurement Accuracy

- Capture high-resolution thermal images at an incredible 1.3 MP (1280 x 1024)

- Measure temperature variance at <30 mK at a minimum +2% accuracy

Applications:

- Research and Development: Materials testing, temperature measurement, and analysis

- Non-Destructive Testing (NDT): Identifying structural defects & anomalies in metals and composite materials

A6701 MWIR Package w/ Macro Lens & Stand

Package Features

- FLIR A6701 MWIR InSb Cooled Camera, 640 x 512 (327,680) pixel

- 50mm MWIR Macro Lens, 3.0-5.0µm

- Cooled A and X Camera Microscope Stand (4233062)

- Research Studio - Professional Edition - 1 Year License (Online Activation)

Applications:

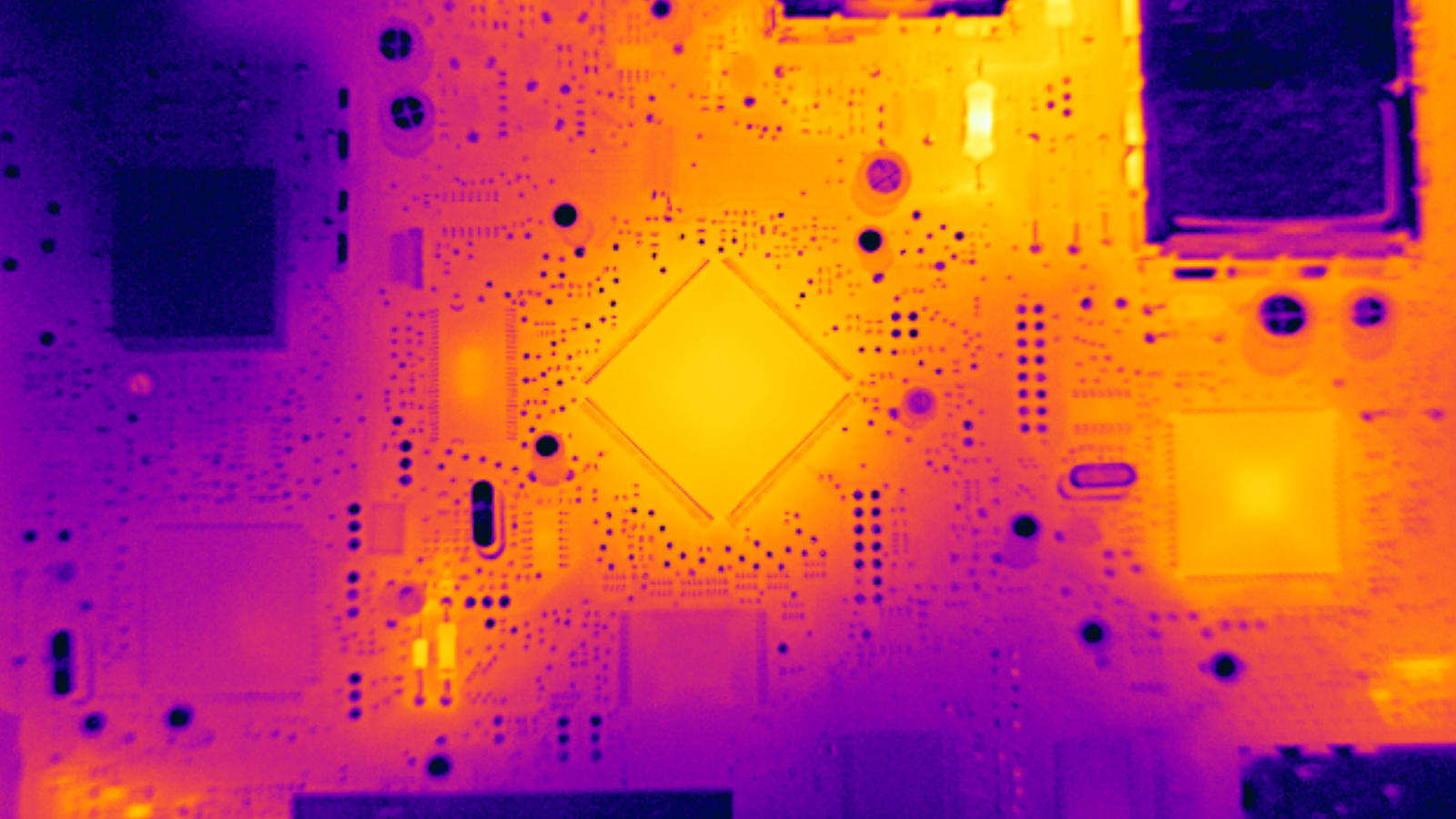

- Non-Destructive Testing (NDT): Tracking and analysis of high-speed events and objects, ideal for aerospace and automotive inspection and testing

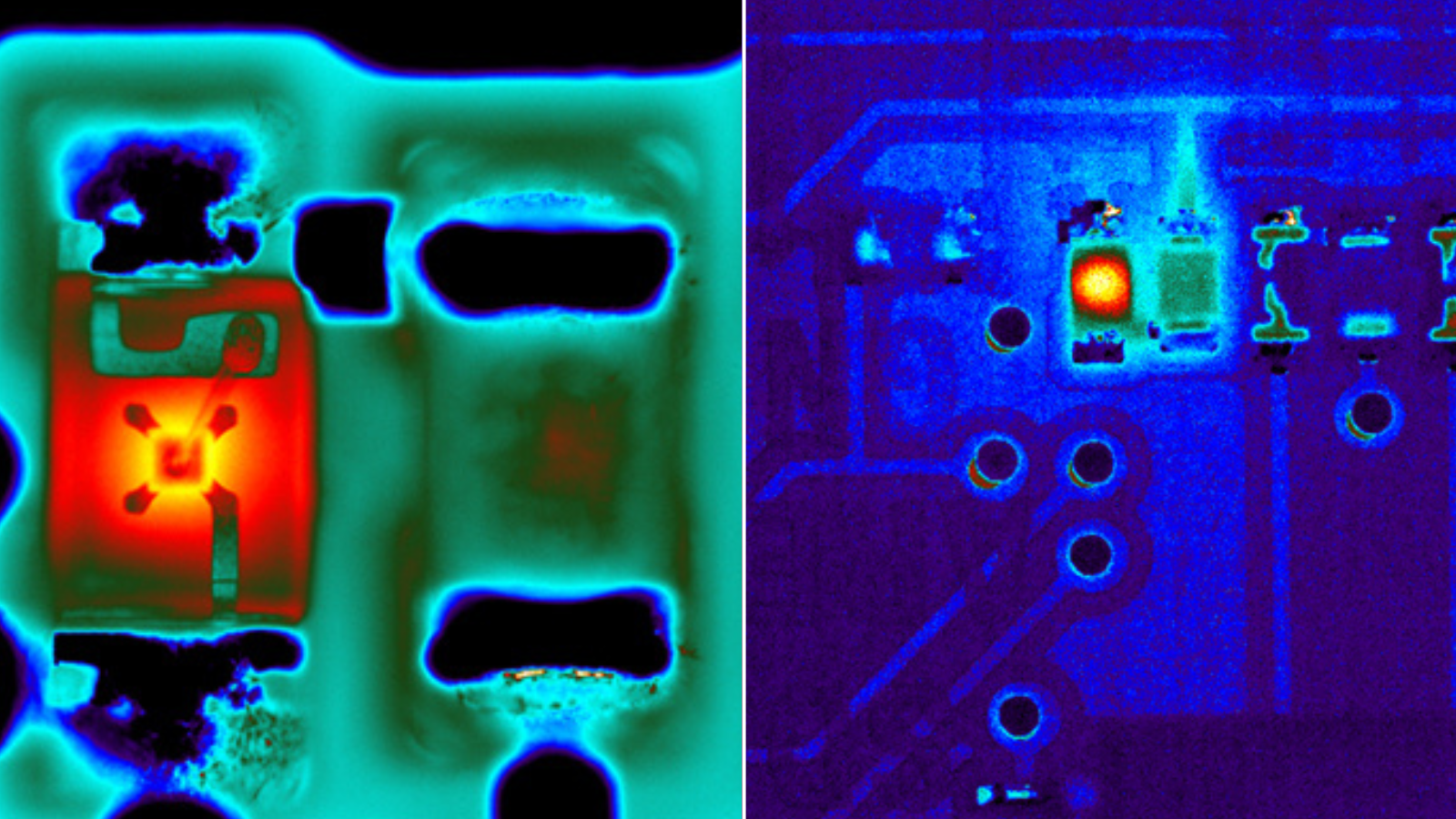

- Electronics Inspection: Identifying deficiencies in electronic equipment and systems to enable further optimisation and greater power efficiency

What is an Uncooled Camera?

Uncooled infrared cameras differ from their cooled counterparts as they don't need extreme cooling. They use microbolometers, a small vanadium oxide resistor possessing a substantial temperature coefficient placed on a silicon element featuring a generous surface area, minimal heat capacity, and effective thermal isolation.

These cameras target the Longwave Infrared (LWIR) spectrum from 7 to 14 microns in wavelength, capturing the infrared energy emitted by objects. Their combination of microbolometer technology and LWIR focus makes them efficient tools for various applications like security, diagnostics, and research.

Benefits of Uncooled Cameras

Lower Entry Cost

Uncooled thermal cameras often come at a significantly lower cost compared to their cooled counterparts. The manufacturing process of uncooled sensors is more streamlined, resulting in higher production yields and lower expenses.

Additionally, uncooled cameras avoid the need for expensive cryocoolers and intricate vacuum packaging that cooled cameras demand. This cost-effectiveness makes uncooled cameras an attractive choice for various applications.

Energy-Efficiency

The power consumption of uncooled cameras is significantly lower than that of most cooled thermal cameras, largely due to the energy requirements of the cryogenic cooling system.

This energy efficiency not only minimizes operational costs but also extends battery life where applicable, making uncooled cameras an economical and practical choice for various applications where long-term, continuous monitoring is essential.

Reliability

Unlike cooled cameras equipped with cryogenic coolers that are very maintenance-heavy, uncooled cameras are much easier to operate. This reliability stems from their simpler design and lack of reliance on complex cooling systems.

This remarkable reliability not only enhances workflow efficiency but also ensures uninterrupted data collection and analysis, making uncooled thermal cameras a reliable and practical choice for a diverse range of applications.

Disadvantages of Uncooled Cameras

- Lower Resolution: The lenses and sensors in uncooled cameras typically operate at a lower resolution and can cause a reduced quality of images and thermal information available to the user.

- Smaller Detection Range: The limited sensitivity of uncooled cameras can impact their detection range, making it harder to detect smaller or distant heat sources compared to cooled cameras.

- Reading Interference: Images captured from uncooled thermal cameras can be susceptible to interference, either from factors within the image such as noise or artifacts, to external IR radiation sources. these sources of interference can degrade the overall accuracy of readings and temperature measurements from the camera.

Recommended Uncooled Cameras

FLIR A700sc Series Science Kit

Professional Kit Features

- FLIR A700 Image Streaming Camera w/24° lens with automatic/remote and manual focusing

- FLIR Macro Mode for superior system flexibility

- FLIR Research Studio Professional Edition (1-year License)

Applications:

- Thermography and NDT: Identifying defects, leaks, and anomalies within machinery, electrical systems, and structures, aiding in efficient maintenance and troubleshooting.

- Materials Science: Exploring material thermal properties, encompassing heat distribution, thermal conductivity, and phase transitions.

FLIR T-Series Uncooled Cameras

Fast, Flexible & Accurate in Any Environment

- Capture high-resolution thermal images at an incredible 1.3 MP (1280 x 1024)

- Measure temperature variance at <30 mK at a minimum +2% accuracy

Applications:

- Industrial Inspection: Inspecting electrical equipment and industrial assets, detecting temperature hotspots, loose connections or fluid leaks

- Thermal Inspections: Simplifying outdoor inspections in low-light environments, detecting hotspots and accurate temperature measurement of small targets

Conclusion

To conclude, there isn't a single right answer for which type of camera is better. Having explored several of the benefits and flaws of both camera types and furthering our understanding of their capabilities, we will help you make an informed decision for the camera that best meets your requirement, application needs and budget.

At SJ Electronics, we're here to guide you toward the right choice for your thermal imaging journey. If you'd like to know more about our diverse portfolio of thermal imaging cameras, cooled, uncooled, and everything in between, you can get in touch with our expert team of engineers by emailing us here at sales@sjelectronics.co.uk or by calling directly at 01536 416200.

Contact Us Now

Fill out the form below and a member of our team will get in touch shortly.