Illuminating the World: The Versatility of LEDs

LED has revolutionised numerous industries with its versatility. Widely employed in lighting, LCD display backlights, mobile phones, information displays, and status indicators, LEDs are also integral to cutting-edge applications like information transmission (such as IrDA infrared transmission and Li-Fi optical communications technology, also known as Light Fidelity), signal conversion (including infrared thermal imaging and optocouplers), and even biomedical applications like UV sterilisation.

To ensure the accuracy and consistency of LED performance, characteristic tests are crucial. These tests, akin to those conducted for conventional light sources, involve measuring parameters such as luminous flux, luminous intensity, luminance, and illuminance. These measurements adhere to standardised methods established by the International Commission on Illumination (CIE). Subsequent standards like CIE1931 and CIE1976 have become the bedrock of colorimetry, shaping the way we understand and harness LED technology for diverse applications.

From enhancing the brightness of our screens to advancing the frontiers of communication and healthcare, LEDs continue to illuminate our world, offering endless possibilities in the realms of technology and innovation.

Precision Testing for LEDs: Tools and Techniques

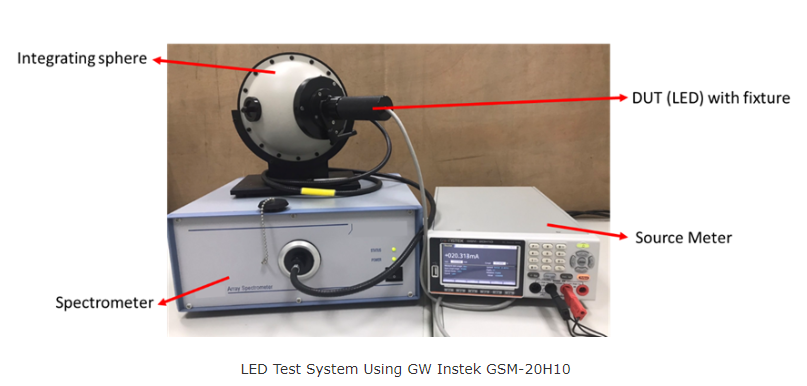

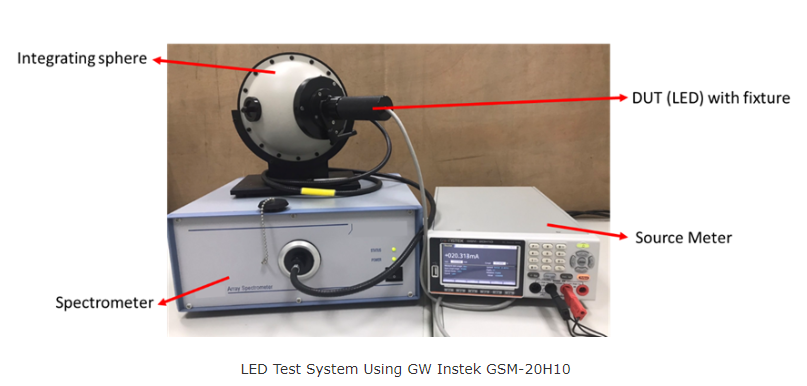

Evaluating the characteristics of LEDs demands sophisticated equipment, including spectrometers, integrating spheres, and source measure units. The process involves a meticulous connection method: a computer oversees the output from the power source, typically a source measure unit, and guides the measurements at the light source receiver, often a spectrometer. This precise coordination ensures controlled and accurate LED testing, essential for illuminating innovations across various applications.

Optimising LED Testing: A Step-by-Step Approach

Efficiently testing LEDs using a source measure unit involves a structured process:

- Configure Output: Set the source measure unit's output voltage and current based on the LED's rated specifications, typically ranging from μA to mA for current and within 20V for voltage.

- Connect Terminals: Link the positive and negative terminals of the source measure unit to the corresponding LED terminals. Adjust the current and voltage accordingly.

- Choose Mode: Select the power supply mode—either constant current (CC) or constant voltage (CV) mode—based on the LED's requirements.

- Adjust Parameters: Fine-tune output parameters, including current, voltage, and measurement time, as per testing needs.

- Initiate Test: Start the source's output and commence measurement procedures.

- Analyse Results: Evaluate LED characteristics, such as forward current and operating voltage, using the meter readings.

A comprehensive LED assessment encompasses data like spectral graphs, illuminance, and color temperature. Additionally, meticulous recording of each measurement's parameters and values is vital. In the context of this article, testing was executed in alignment with the color quality TM30 regulations, ensuring comprehensive LED evaluation. Notably, engineers meticulously documented voltage variations under CC mode, providing valuable data for in-depth characteristic analysis.

By following these systematic steps and incorporating detailed recording protocols, LED testing becomes not only precise but also an insightful process, enabling engineers to gain deeper insights into LED behavior and performance.