Unleashing Precision: Advanced Thermal Imaging Cameras for Every Application

For decades, thermal imaging cameras have stood as indispensable tools, championed by scientists, researchers, and R&D specialists across multifarious domains. Their applications span the vast landscape of industrial R&D, academics, non-destructive testing (NDT), materials testing, and defence and aerospace. Yet, in this diverse tapestry of uses, one truth remains: not all thermal cameras are crafted with the same calibre.

In certain critical applications, precision is paramount. That's where dedicated, advanced thermal cameras come into play. These technological marvels are equipped with high-speed stop-motion capabilities, setting them apart from the ordinary. Why settle for less when superior accuracy and real-time measurements can be your norm?

At the forefront of innovation, these specialised thermal cameras redefine what's possible. They ensure accurate measurements that are vital for scientific breakthroughs, groundbreaking research, and meticulous testing processes. Don't compromise when it comes to your thermal imaging needs. Choose excellence, choose accuracy – choose advanced thermal cameras tailored for your specific requirements.

Choosing the Right Thermal Imaging Camera for Your Needs: A Critical Decision

Selecting the ideal thermal imaging camera is not a one-size-fits-all endeavour. To ensure accuracy and efficacy, understanding your specific spectral requirements is paramount. This knowledge guides us in making the correct detector selection, laying the foundation for precise thermal imaging results.

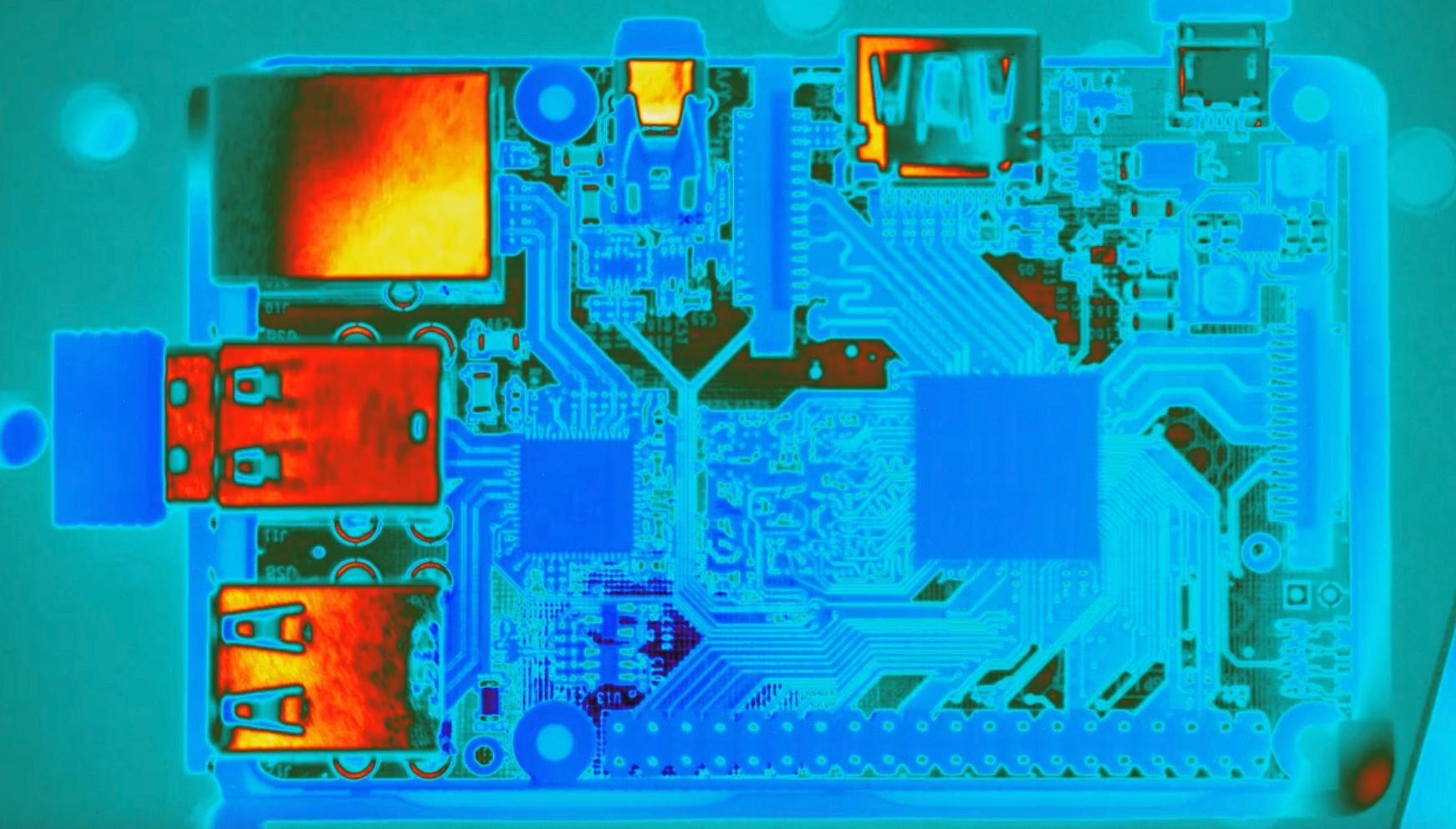

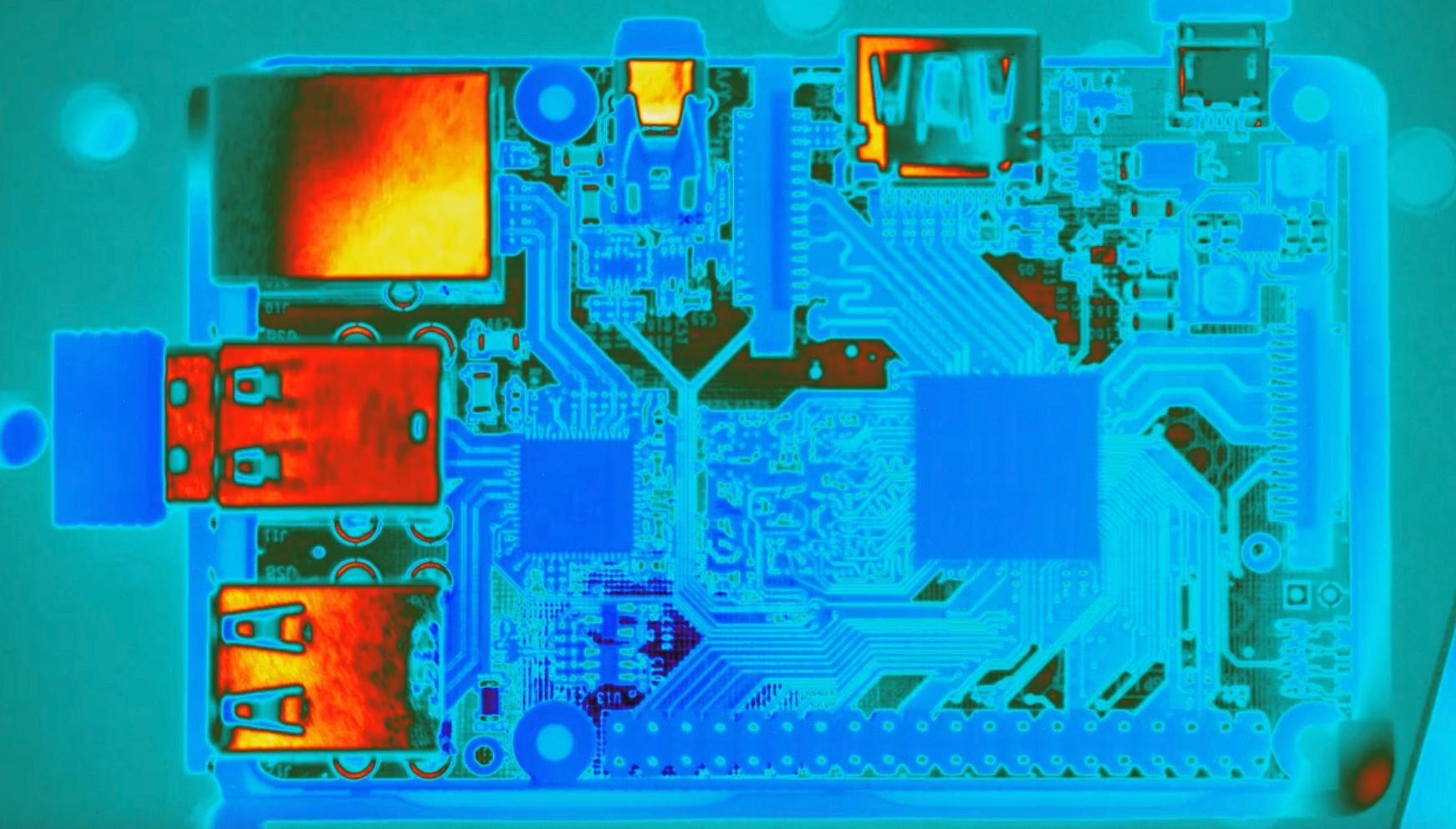

In the realm of Science and R&D applications, thermal imaging cameras emerge as powerful allies. They are not merely tools; they are non-invasive marvels that empower you to identify issues in the early stages of the design cycle. Early detection allows for meticulous documentation and correction, preventing minor glitches from snowballing into serious, costly repairs.

Yet, with great power comes a crucial decision: should you opt for a cooled or an uncooled thermal imaging system? This pivotal choice defines the course of your thermal imaging endeavors. Cooled and uncooled systems represent the two distinct classes available in the market today. Their component costs vary significantly, adding complexity to the decision-making process.

This choice is not just about cooling mechanisms; it's about cost-effectiveness, precision, and long-term value. We understand the intricate balance you need to strike, and we're here to guide you.

Your requirements are unique, and your thermal imaging solution should be equally distinctive. Let's embark on this journey together, ensuring that your thermal imaging investment aligns perfectly with your vision and objectives. Choose wisely, choose informed, and let your thermal imaging endeavors unfold with unmatched precision.

Unraveling the Precision: Cooled Thermal Imaging Cameras at a Glance

In the realm of thermal imaging technology, cooled thermal cameras stand as exemplars of precision and sensitivity. These modern marvels integrate an advanced imaging sensor with a cryocooler, a device engineered to lower the sensor's temperature to cryogenic levels.

Why this extreme cold, you ask? The answer lies in the pursuit of perfection: by reducing the sensor's temperature to these cryogenic levels, we effectively diminish thermally-induced noise to a level that is imperceptible against the signal emanating from the scene being captured.

Cooled thermal imaging cameras, therefore, emerge as the epitome of sensitivity. They possess a unique ability to detect even the minutest temperature differences between objects, elevating them to a league of their own in the world of thermal imaging. Operating within the mid-wave infrared (MWIR) band and the long-wave infrared (LWIR) band of the spectrum, these cameras harness the power of blackbody physics. In this domain, thermal contrast reigns supreme—a measure of signal change corresponding to alterations in target temperature.

Why does thermal contrast matter? Because it defines our ability to discern objects against backgrounds that might not differ significantly in temperature from the object itself. The higher the thermal contrast, the easier it becomes to detect objects, making cooled thermal imaging cameras indispensable in scenarios where precision and clarity are non-negotiable.

In the intricate dance between technology and the unseen world, cooled thermal imaging cameras emerge as the silent guardians, revealing nuances imperceptible to the naked eye. Witness the invisible, capture the subtle, and embrace a world of precision with cooled thermal imaging technology.

Embracing the Heat: Uncooled Infrared Cameras Redefined

In the fascinating world of thermal imaging, uncooled infrared cameras stand as technological marvels, setting a new standard in efficiency and affordability. Unlike their cooled counterparts, these cameras do not rely on cryogenic cooling, making them versatile and cost-effective solutions for various applications.

At the heart of uncooled infrared cameras lies an ingenious design featuring microbolometers—a minuscule vanadium oxide resistor with an impressive temperature coefficient. These microbolometers are carefully integrated into a silicon element, boasting a large surface area, low heat capacity, and excellent thermal isolation. The magic happens when scene temperatures fluctuate, causing corresponding changes in the bolometer temperature. These fluctuations are then transformed into precise electrical signals, ultimately forming a detailed thermal image.

Uncooled sensors find their niche in the Longwave Infrared (LWIR) band, where terrestrial temperature targets predominantly emit their infrared energy. This specialisation makes them ideal for a plethora of applications, capturing thermal nuances with exceptional clarity.

One of the standout features of uncooled cameras is their affordability. The manufacturing process for these sensors involves fewer steps, ensuring higher yields in comparison to their cooled counterparts. Additionally, uncooled cameras eschew the need for costly cryocoolers, making them accessible without compromising on quality.

Furthermore, these cameras are engineered with simplicity in mind, boasting fewer moving parts and remarkably long service lives. Their robust design ensures durability, providing consistent performance even under challenging operating conditions.

In essence, uncooled infrared cameras redefine thermal imaging accessibility. They offer a gateway to the unseen world, capturing thermal intricacies with unmatched precision and longevity. Embrace the future of thermal imaging with uncooled cameras—a fusion of innovation and affordability, designed to illuminate the unseen.

Revealing the Unseen with Cooled Thermal Imaging Cameras: Where Precision Meets Speed

In the realm of thermal imaging, the speed of capturing dynamic scenes is often the differentiator between mere observation and detailed analysis. Cooled thermal imaging cameras, with their remarkable imaging speeds, redefine the possibilities, enabling microsecond exposure times that freeze the motion of even the most dynamic scenes. This capability allows for capturing frame rates surpassing an astounding 29,000 frames per second, making them indispensable tools in a multitude of high-speed applications.

Consider the intricate thermal and dynamic analyses involved in scenarios like jet engine turbine blade evaluations, automotive tire or airbag inspections, supersonic projectile studies, and explosion assessments. In these contexts, the ability to precisely capture rapidly moving objects is paramount. Cooled cameras, with their exceptionally fast response times and global shutter technology, excel in delivering unparalleled accuracy.

The global shutter functionality sets cooled cameras apart. Unlike their uncooled counterparts, which read pixels line by line, cooled cameras read out all pixels simultaneously. This pivotal distinction enables cooled cameras to capture sharp, clear images and take precise measurements of moving objects without any blurring.

In essence, cooled thermal imaging cameras are not just tools; they are gateways to precision, offering a vision of the unseen with unparalleled speed and clarity. In the fast-paced world of dynamic thermal analysis, these cameras stand as pillars of accuracy, ensuring that even the swiftest of motions can be meticulously studied and understood.

Unveiling the World in Unprecedented Detail: The Magnifying Power of Cooled Thermal Cameras

In the intricate world of thermal imaging, magnification capabilities play a pivotal role in unraveling the subtlest of details. Cooled thermal cameras, owing to their ability to sense shorter infrared wavelengths, stand at the forefront of this magnification revolution. This unique trait empowers cooled cameras to achieve unparalleled close-up views, delving into microscopic realms that were once beyond reach.

The secret lies in their superior sensitivity characteristics. Cooled cameras exhibit remarkable sensitivity, allowing the use of lenses with more optical elements or thicker elements without compromising the signal-to-noise ratio. This flexibility ensures that even with complex lens configurations, the image quality remains pristine, preserving the integrity of the captured data.

The ability to capture intricate details with such precision opens doors to groundbreaking research, meticulous inspections, and unparalleled analysis. In the realm of thermal imaging, where every detail matters, cooled cameras redefine our understanding of magnification, inviting us to explore the world in extraordinary detail.