Adeas and BINDER creating the best conditions for your solution

Requirements:

- Testing of electronic products and systems

- Testing of thermal design of the whole system

- Specification conformance

- Soft air flow circulation with homogeneous climate conditions

- Reliable test results

BINDER Solutions:

- Environmental simulation chamber MK115 >

- Wide temperature range

- Precise temperature control

- Controls accessible from the front

- Uniform circulation

- High temperature performance

- BINDER individual solution

- Cyclic temperature testing

Adeas is an independent design house based in Eindhoven, The Netherlands developing customer specific electronic products and systems. By combining creativity, knowledge and experience Adeas turns ideas into solutions realizing the specific wishes of its clients. Adeas aims to support companies active in professional and industrial markets such as broadcast, printing, semiconductor and multimedia industries as well as defence and high tech machinery. The company has a proven track record in successful development of electronic modules, products and embedded systems for multinationals as well as small cap clients.

Technological progress never stops

The design house operates in the forefront of technology and continuously invests in expanding the knowledge and skills of her project teams. This is done by continuous training and intensive cooperation with technology leaders in electronic components, tooling and equipment.

Increasing high speed and functionality demands

Customers demand more and more functionality and speed from electronic systems making high speed connections to the outside world and direct memory access a necessity. To achieve these goals Adeas uses the latest generation FPGA semiconductor devices. These devices offer high speed transceiver technology and a vast amount of logical cells enabling Adeas to implement complex functionality.

Headquater Adeas Eindhoven, Neatherlands

Specification conformance

The complexity of these devices and systems tend to lead to increasing power consumption and dissipation resulting in the necessity of a proper thermal design of the whole system. Operation of a system beyond the specified temperature limits of the components can lead to erroneous behaviour. This can for instance be caused by the timing behaviour of a FPGA which varies with device temperature. Many other devices within a system can be affected if operated outside specified temperatures, causing non conformance to the system specifications.

"With the environmental simulation chamber from BINDER, we can verify that the electronic systems we develop meet the specification requirements of our customers."

Guido Peulen, Senior Designer electronics

Adeas has purchased the BINDER MK115 environmental test chamber to verify that the systems it develops meet the specification requirements at the temperature limits as requested by the customer. Moreover, it enables Adeas to test how the system performs outside these temperature limits and makes it possible to carry out durability analysis at various temperatures.

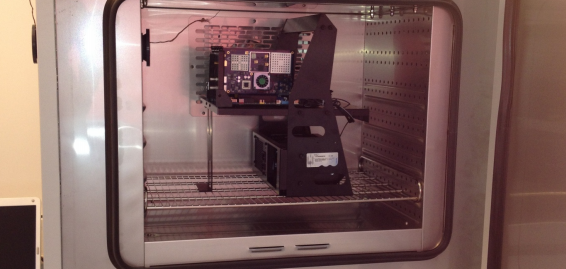

Temperature testing of a PCI express card

Wide temperature range with gentle airflow

Due to its wide temperature range and very accurate temperature control, the MK115 from BINDER provides optimal conditions for complex test requirements. In addition, the chamber is very well suited for this range of applications because of its particularly gentle airflow. "With the environmental simulation chamber from BINDER, we can verify that the electronic systems we develop meet the specification requirements of our customers," says Guido Peulen, Senior Electronics Designer, about the use of the environmental simulation chamber. Among other reasons, the design engineer prefers the MK115 due to a customer specific BINDER Individual solution. This function ensures that homogeneous temperature distribution in the inner chamber remains constant when airflow is reduced, thus preventing unwanted cooling of the electronic components.

"Made in Germany" quality

For Adeas clientele, the "Made in Germany" designation is very important. The design house has also set itself the target of a high commitment to quality to service its clientele with the best solutions. At the same time, employees praise the simple operating philosophy of BINDER chambers and see an absolute advantage in the comprehensive service offering of BINDER. With the BINDER MK115 Adeas has an evaluable tool to help develop high quality systems and provide its clients with a leading edge.

Advantage

- BINDER APT.lineTM

- Temperature range -40 °C bis 180 °C

- User friendly LCD screen

- Easy-to-read menu guide

- Made in Germany

Areas of application

- Automotive

- Elektronics / Semiconductor industry

- Plastic Industry

- Aerospace / Defence Industry